-

About LiM

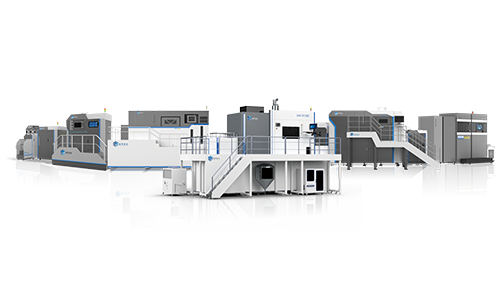

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

News information

Popular Articles

LiM Laser AMS-SLM pre-processing software independently developed by LiM Laser is suitable for the company's own laser selective melting equipment. Its functions include digital model creation, 3D STL part import, 2D CLI profile data import, part movement/rotation/slicing/path planning, etc.

2024-01-24

With the accelerated development of the manufacturing industry, enterprises have increasingly stringent requirements for mold accuracy, structural complexity, production cycle and cost, and traditional mold manufacturing technology can no longer fully meet market demand. Among the many new technologies, metal 3D printing technology brings a new development direction for the mold industry with its unique technical advantages.

2023-08-07

Strengthening management is the eternal theme of enterprise development. As the domestic head of metal 3D printing equipment manufacturer, LiM Laser fully implements lean management requirements and takes quality management as the top priority. In this process, LiM Laser Science uses "5M1E1I" and other analytical tools to solve problems and improve methods, and on this basis, it has established a complete quality management system to promote the high-quality development of the enterprise.

2023-07-31

Market Activity