-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

Service Support

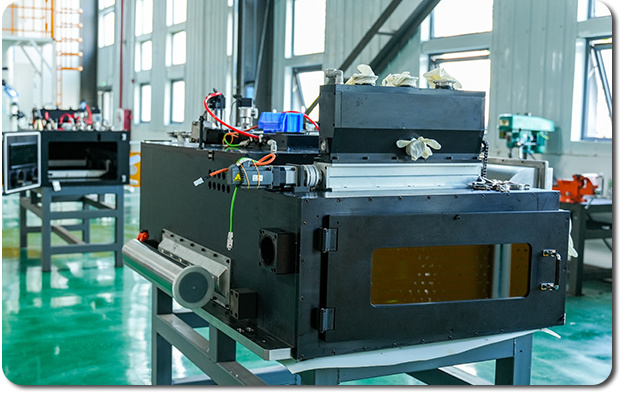

3D printing equipment quality management

In the face of fierce market competition, LiM Laser takes quality management as its top priority and establishes a complete management system to ensure that equipment and printed products meet relevant quality management system standards. Strict control of all aspects of the production process with high-quality products and services to meet user needs, to establish a good customer relationship.

Raw material quality assurance

All key optical components are selected from foreign high-end brands, and equipment materials are selected in line with relevant standards; The use of internationally renowned brand parts to ensure printing stability, to ensure equipment quality and service life in line with standards.

Production process quality assurance

Through continuous improvement, the establishment of efficient and safe assembly process, manufacturing in strict accordance with the process flow, the whole process control and inspection of key processes, comprehensive testing of products, to ensure that the equipment indicators meet the requirements.

Finished product quality assurance

Before leaving the factory and shipping, all the equipment must be checked again, and the professional team will carry out comprehensive mechanical, optical, electrical, software and other tests to check the safety of the equipment, the integrity of the equipment, the appearance quality and the performance test of the printed finished parts can meet the delivery requirements.

3D printing service quality management

In the face of fierce market competition, LiM Laser takes quality management as its top priority and establishes a complete management system to ensure that equipment and printed products meet relevant quality management system standards. Strict control of all aspects of the production process with high-quality products and services to meet user needs, to establish a good customer relationship.

Raw material quality assurance

Incoming inspection is a vital part of quality management, LiM Laser strictly tests the quality of raw materials, and establishes an incoming inspection database, which regularly reviews and updates incoming inspection procedures and standards to ensure that they comply with the latest quality requirements and standards.

Production process quality assurance

The laser metal 3D printing equipment is equipped with self-developed monitoring system to monitor the printing status in real time:

The oxygen content of the forming chamber is monitored, and the alarm is automatically given when the limit is exceeded.

It is equipped with powder bed monitoring module and built-in HD camera to record the powder bed condition, monitor the powder laying quality and melting quality of each layer, and automatically replenish the abnormal powder laying powder to ensure that the processing process can be traced and the quality of the printed product is stable.

Finished product quality assurance

After the printing is completed, the finished products will be inspected in a comprehensive manner, including performance testing, internal quality testing, surface defect testing, internal quality testing, etc., to ensure that the product performance and appearance quality meet the needs of users.

You can also submit information online, and we will reply to you within 24 hours!