Automotive Manufacturing Solutions

Automobile Making

Automobile Manufacturing解决方案

Overview

Metal 3D printing technology runs through almost the entire cycle of automobile manufacturing, including research and development, production and use. At present, the experimental model and functional prototype manufacturing, which are mainly used in the R & D process, can greatly improve R & D efficiency, reduce R & D costs, and improve component performance. In addition, the manufacture of metal parts for automobile tire molds and automobile seats will also be applied to metal 3D printing technology. With the continuous development of metal 3D printing technology, its application in the automotive industry will expand to the production and use of larger market space, providing more development opportunities for automakers.

undefined

Technical advantages

Cost Reduction

Reduce material scrap rate and reduce labor input

High Efficiency

Reduce processes and shorten the development cycle.

High Quality

Digital production, stable quality of parts

Lightweight

Optimize structural design, take into account product performance while achieving part weight reduction

Personalization

Customized according to needs, design more free

Breakthrough In Complex Structure Forming

No need to open the mold, integrated forming

Application Case

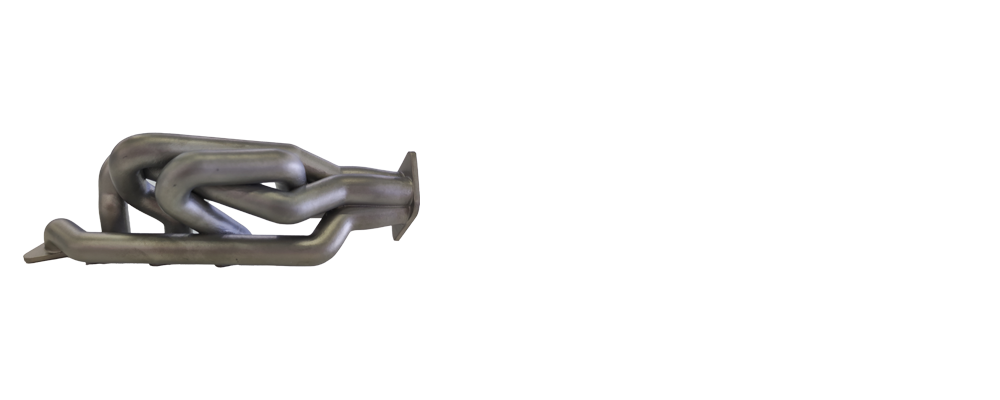

Engine Manifold

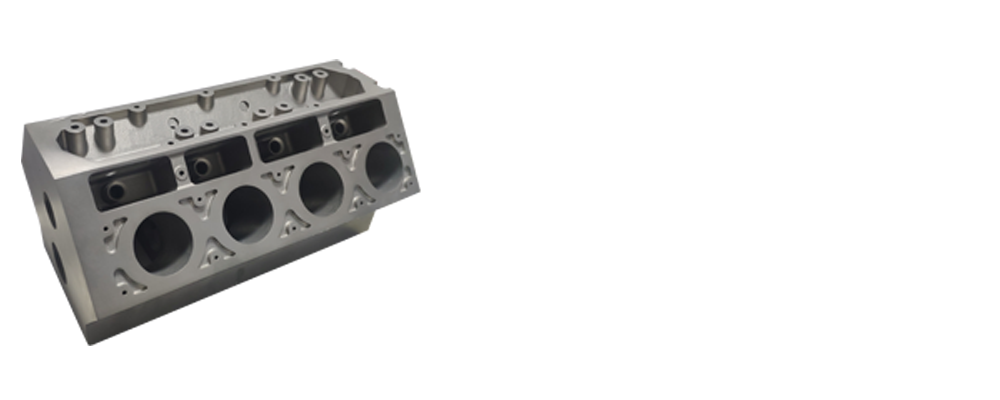

Engine cylinder body reduction parts

Recommended Equipment

Related News