Customer Case · Automotive Industry | LiM Laser Joins Hands with Foton Cummins to Help the Industry Lead

Author: LiM Laser

Time:2022-04-13

The application scenarios of 3D printing in the automotive industry

Metal 3D printing plays a crucial role in the field of automotive design and development, especially in the verification of engine intake and exhaust side components, with outstanding advantages. Traditional metal components in automotive development and design often require molds, which have long cycles, low efficiency, and high costs, making it difficult to quickly produce and verify metal prototypes. After adopting metal 3D printing technology, designers can not only make the model design lighter, more complex, and perform better, but also design a good model with low cost and shorter process. Through metal 3D printers printing and simple post-processing within a few hours or tens of hours, the physical model can be obtained. After the physical model is assembled, a 1:1 assessment experiment can be conducted. If any unreasonable design is found, the model can be modified immediately, and printing and verification work can be carried out again. Once the final model is confirmed to be correct, it can be mass-produced. This approach greatly accelerates the iteration cycle of automotive design updates, which also provides favorable conditions for technological innovation in the automotive industry.

Beijing Foton Cummins Engine Co., Ltd. (hereinafter referred to as "Foton Cummins") was established in 2008. It is a joint venture between Cummins, a leading global power solution provider, and Chinese commercial vehicle enterprise BAIC Foton Automotive Co., Ltd. It is an advanced diesel engine production base in the world, mainly producing light, medium, and heavy-duty diesel engines. The factory has an engine manufacturing system designed according to world leading technical standards and quality control standards. The production equipment is highly automated, and the products mainly include F series and X series engines with different displacements. The annual production capacity can reach 520000 units.

Fukuda Cummins purchased LiM laser 3D printing equipment LiM-X260A

Around 2019, Foton Cummins began using metal 3D printing technology for the research and verification of engine intake and exhaust side components. During this process, Tianjin Laiming Laser Technology Co., Ltd. (hereinafter referred to as "Laiming Laser") provided excellent technical support to Foton Cummins. In July 2020, Foton Cummins purchased the first LiM-X260A metal laser selective melting equipment from Radiant Laser for upgrading and innovating engine parts and technology, laying a solid foundation for cooperation between the two parties.

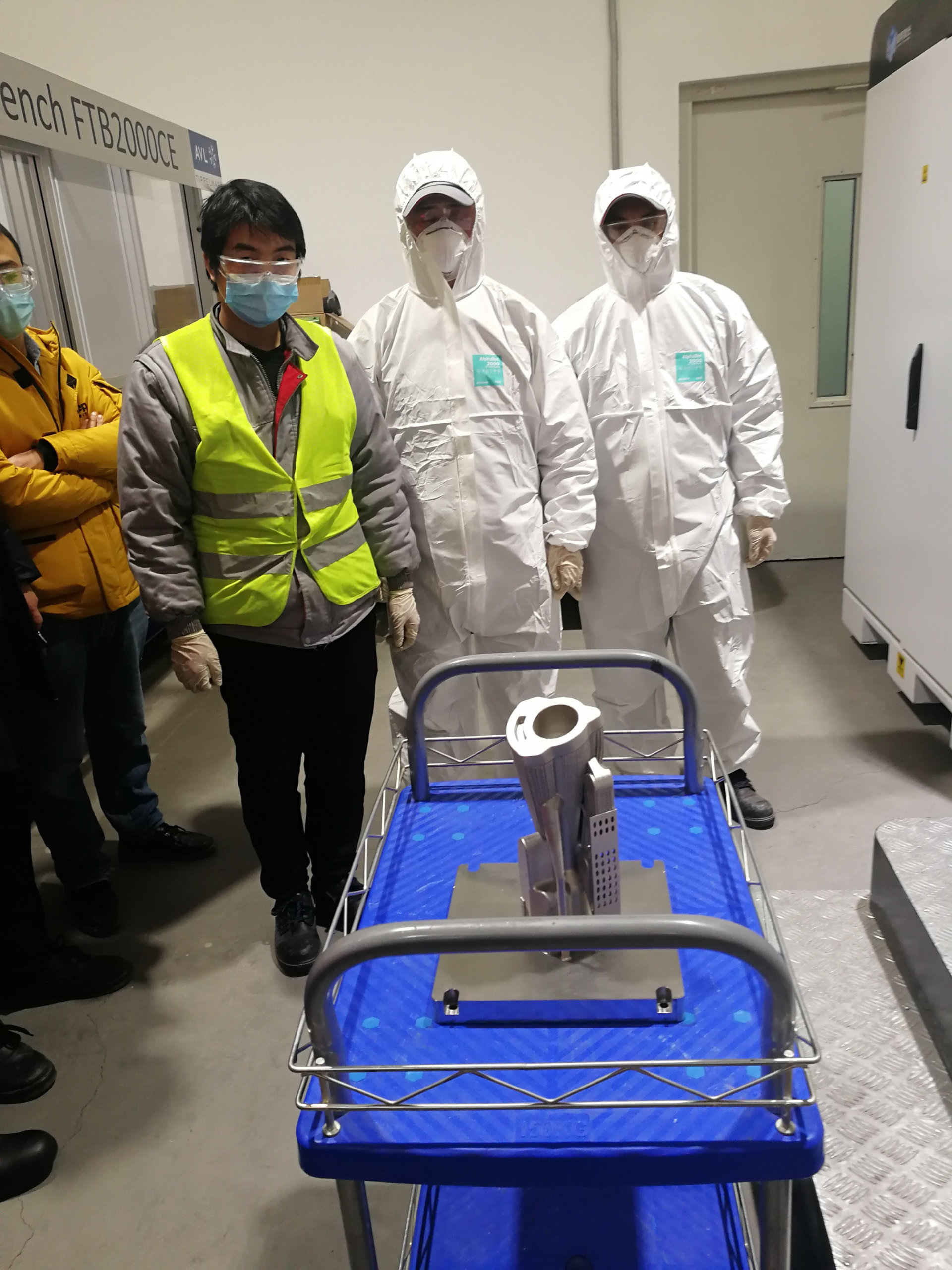

Foton Cummins completes first print

LiM laser metal 3D printing equipment LiM-X260A.Help Foton Cummins to quickly realize innovation verification

Zhang Bo, Senior Engineer at Foton Cummins Testing Center, told us: "Foton Cummins has more than ten companies in China. During product development, we found that many parts cannot be used with the original model during the upgrading and innovation process. When improving one size or part, several different sizes of the same part may be made. If a mold is opened, the cost will be very high and the cycle will be long.". To quickly implement this concept and do some validation, we have considered using metal 3D printing technology Zhang also emphasized, "In the process of developing the X12N natural gas heavy-duty engine, we need to modify the air pipes used in this type of engine. The size and structure of the parts need to be modified, and various parts of different sizes need to be used for verification. We used LiM-X260A metal laser selective melting equipment with laser for 3D printing, which is easy to achieve.". The printed parts have withstood rigorous testing under extreme conditions of about 750 ℃, greatly saving development costs and improving validation efficiency, solving a major challenge for us and shortening the entire product validation cycle

Foton Cummins printed parts using LiM-X260A

Professional win customer trust, laser assisted industry development

During the cooperation with Foton Cummins, Radiant Laser quickly responded to demands, provided timely support, and effectively ensured the timeline of each project. "I am very satisfied with the technical support and after-sales response speed of Lasmin Laser", said Zhang Gong. "The after-sales colleagues of Lasmin are very awesome. When we contact them, they can give us quick answers no matter on weekdays or at night. The after-sales service is on standby 24 hours a day. The equipment has been in stable operation for 18 months, and the frequency of use is also high. We are very relieved by the safe and stable operation of the equipment. Under the impact of the epidemic, traveling is very inconvenient. The rapid manufacturing of metal 3D printing has reduced many unnecessary troubles for us and also helped us solve many practical problems.

With the continuous development of 3D printing technology, prototype production, lightweighting, and mass production will be further deepened in the future, and 3D printing will be applied more widely. We also look forward to further cooperation with Foton Cummins to provide deeper solutions for automotive industry users and help promote more efficient innovation and development in the automotive industry.

Related Articles

Market Activity