Customer Case-Steel Industry Event LiM Laser 3D Printing Makes Baoshan Steel Equipment "Reborn"

Author: LiM Laser

Time:2022-04-20

Metal 3D Printing - Digital Green Intelligent Manufacturing Technology

In recent years, the country has vigorously developed a circular economy and promoted resource conservation and intensive utilization. In July 2021, the National Development and Reform Commission issued the "14th Five Year Plan for the Development of Circular Economy", which deployed five key projects including the construction of urban waste material recycling systems and six key actions for the high-quality development of the remanufacturing industry. Conducting scientific research and engineering applications in remanufacturing is of great significance for ensuring national resource security, helping to achieve carbon peak and carbon neutrality, and promoting ecological civilization construction. At present, remanufacturing has been widely used in fields such as steel, nuclear power, coal mines, automobiles, civil aviation, and molds. The process of remanufacturing involves repairing and transforming waste products through digital technology to restore their original value. This remanufacturing process can generally save energy by over 60%, materials by over 70%, and costs by over 50%. Some remanufactured products can even exceed the performance of prototype new products, which not only has good economy, but also is more convenient and efficient. Especially for products that have been imported or discontinued in the early stage, remanufacturing is basically the only solution, and metal 3D printing remanufacturing is currently one of the most cutting-edge technologies.

China Baowu - Smart Steel Promotes the Industrialization Development of 3D Printing

China Baowu Iron and Steel Group Co., Ltd. (referred to as China Baowu) was formed through the joint restructuring of the original Baosteel Group Co., Ltd. and Wuhan Iron and Steel (Group) Co., Ltd. Baowu Group bears the historical responsibility of China's steel industry transformation and upgrading, and smart steel is an important lever for promoting the supply side structural reform of the steel industry. As early as 2006, Baosteel applied 3D printing to the steel industry, promoting the further development of 3D printing in the industrial field through projects. In recent years, it has successfully "printed and remanufactured" a series of products such as rolling mill memorial archway, flat head cover, universal joint shaft and foot roll, and has participated in the formulation of multiple industrial standards for laser additive remanufacturing.

LiM-S0402 laser near net forming equipment purchased by Baosteel Central Research Institute

LiM-S0402, a laser near net forming equipment, revitalizes waste parts

By connecting laser 3D printing equipment, metal parts can be directly printed, which not only rejuvenates waste parts but also improves performance and extends lifespan. This is not a science fiction movie, but a manufacturing technology revolution happening around us. In 2020, Baosteel Central Research Institute purchased a laser near net forming equipment LiM-S0402 from Tianjin Radiant Laser Technology Co., Ltd. (referred to as Radiant Laser). Dr. Wu Qiong of the Central Research Institute said, "At that time, a research project was being planned to address the problem of key equipment in the factory losing its function due to wear, cracking, and other reasons during use. The aim was to figure out what methods can be used to repair it and restore its original function, reducing losses. To solve this problem, a series of research was conducted, comparing various technical methods such as welding, spraying, and plasma repair. After comprehensive consideration, a laser 3D printing solution was selected, and LiM-laser near net forming equipment LiM-was purchased through bidding for Radiant Laser." Dr. Wu explained, "Firstly, laser 3D printing has good controllability in terms of energy and shape. Secondly, there is a wide range of materials available for laser 3D printing. Thirdly, the operation and maintenance of laser 3D printing equipment are also relatively convenient. Laser 3D printing has a large demand in steel application scenarios, and many future research and development work will need to rely on this technology.". We use it more in the laboratory for design and simulation experiments, firstly to explore materials and study what materials are used for repair or reinforcement. The second is to explore the process and accumulate reference technology for large-scale production and physical repair. At present, we have developed solutions to multiple on-site problems using this device and applied them to large-scale production.

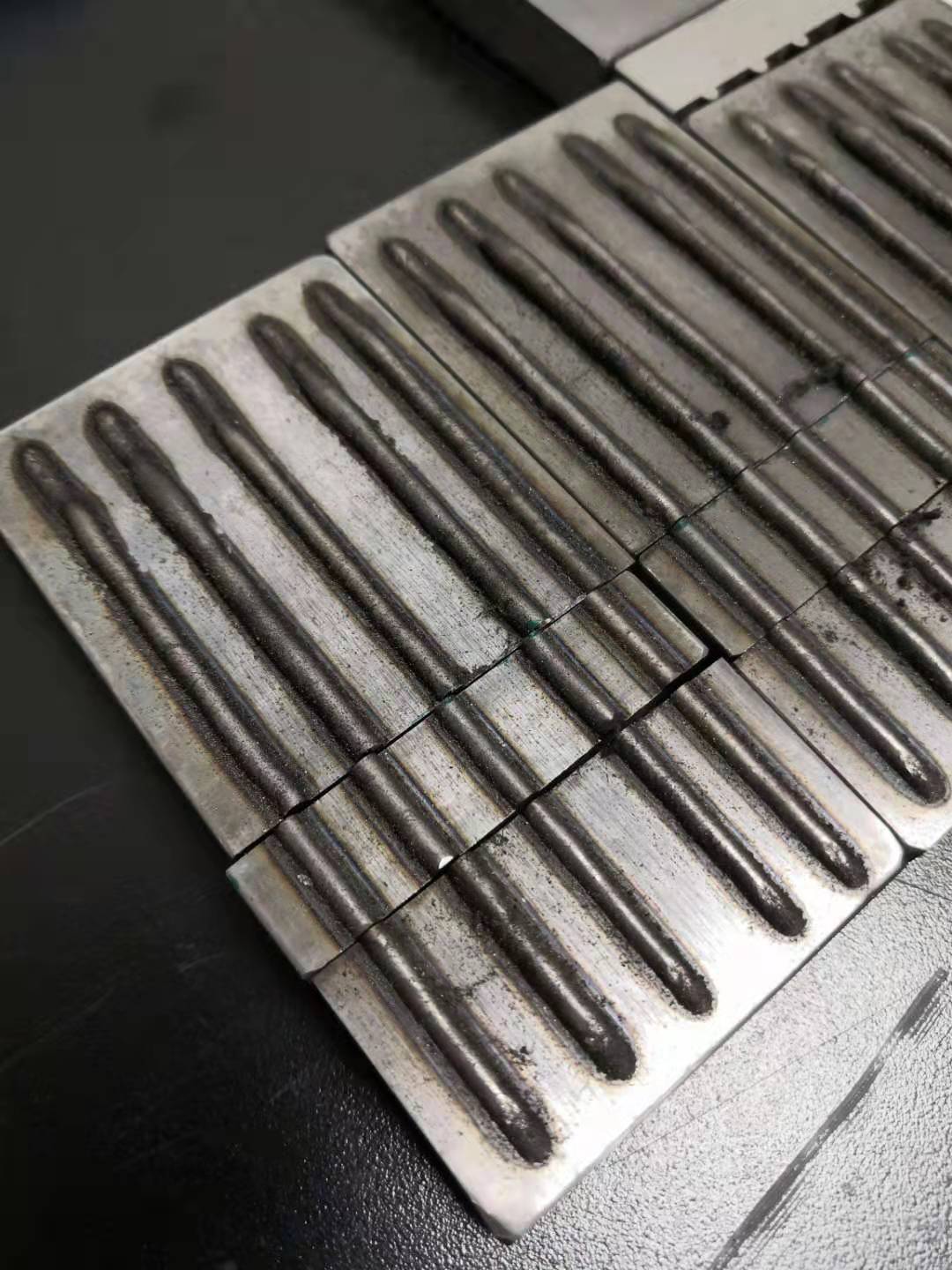

Baosteel Central Research Institute uses LiM-S0402 to repair parts

High efficiency and low-cost 3D printing technology shines brightly in the steel industry

During the process of repairing parts, the cost of re opening the mold is relatively high and does not require mass production. Therefore, 3D printing provides a new approach for product repair. Firstly, by surveying and mapping, a three-dimensional model diagram of the part is established. Then, through slicing processing, the printing path is designed and stored as a file that can be directly read and used by the 3D printer. The file is loaded into the printer, and 3D printing materials are loaded. The printing platform is debugged, printing parameters are set, and finally, the additive processing of the part is completed. By utilizing advanced metal 3D printing additive manufacturing equipment, the most suitable processing technology can be selected based on the working conditions, material characteristics, and production technology requirements of the processed workpiece, improving the wear resistance, corrosion resistance, oxidation resistance, and hot corrosion performance of the metal surface, repairing service damage and manufacturing defects on the metal material surface, and achieving reliable connection of difficult to melt, difficult to weld, and easily deformed metal components.

Baosteel Central Research Institute uses LiM-S0402 to print parts

Professionalism and sincerity win the trust of customers

Laiming Laser Company has over 200 employees, including more than 50 technical research and development teams, mainly from internationally renowned additive manufacturing equipment enterprises and multiple key universities in related fields. More than 50% of team members have over 10 years of experience in product development and lean manufacturing management. The company has more than 70 core technology patents and has obtained various honors and qualifications such as national high-tech. According to Dr. Wu's recollection, "Laser attaches great importance to our project. In the early stage of communication, the project leader had multiple rounds of communication with us, exchanging many opinions on the civilian grade metallurgical industry market, 3D printing and remanufacturing technology, etc. From hardware installation and debugging to software operation demonstrations, Laser provided us with professional and patient guidance. Through this process, our team deepened their understanding of this equipment and was also moved by Laser's sincere service attitude. The two sides established a good foundation for cooperation."

Compared with traditional manufacturing methods, 3D printing technology is not limited by traditional processes and manufacturing resources, greatly reducing development costs, shortening research and development cycles, and breaking through the limitations of traditional manufacturing processes on complex shapes. It brings about a revolutionary change in production and processing concepts, playing an important role in promoting the field of equipment remanufacturing. In the future, Radiant Laser will also strive to expand the extension of laser 3D printing remanufacturing technology and promote the wider application of 3D printing in the industrial field.

Related Articles

Market Activity