Customer Case-Material Industry Event LiM Laser Promots China Machine New Material to Achieve Independent Material Verification

Author: LiM Laser

Time:2022-04-26

Metal Powder Materials - The Key to Metal 3D Printing

Metal 3D printing materials are an important material foundation for the development of metal 3D printing technology. To some extent, the development of materials determines whether 3D printing can have a wider range of applications. The research and breakthrough of metal 3D printing materials are the foundation for the promotion and application of metal 3D printing technology, as well as the fundamental guarantee for meeting printing needs. This is conducive to promoting breakthroughs in the metal 3D printing industry and assisting in the transformation of high-precision and cutting-edge fields such as aerospace, machinery, and medicine. At present, 3D printing is developing rapidly in fields such as aerospace, automotive manufacturing, and medical equipment, and it is the opportunity period for metal 3D printing. Industry insiders believe that metal 3D printing, which has a high concentration in the industry, is expected to experience more significant development on the basis of further innovation in metal materials.

Zhongji New Materials Research Institute (Zhengzhou) Co., Ltd. (hereinafter referred to as "Zhongji New Materials") is a new research and development institution jointly initiated and established by China National Machinery Science Research Institute Group Co., Ltd., Beijing Jike Guochuang Lightweight Science Research Institute Co., Ltd., Zhengzhou Municipal People's Government, and Zhengzhou High tech Zone. Relying on national scientific and technological innovation platforms such as the National Lightweight Material Forming Technology and Equipment Innovation Center, the State Key Laboratory of Advanced Forming Technology and Equipment, the Institute conducts scientific theoretical research, tackling key problems in cutting-edge technology, and transferring and transforming achievements. It has built professional research rooms such as the ultra-high speed laser cladding technology laboratory, 3D printing technology laboratory, and additive manufacturing materials laboratory.

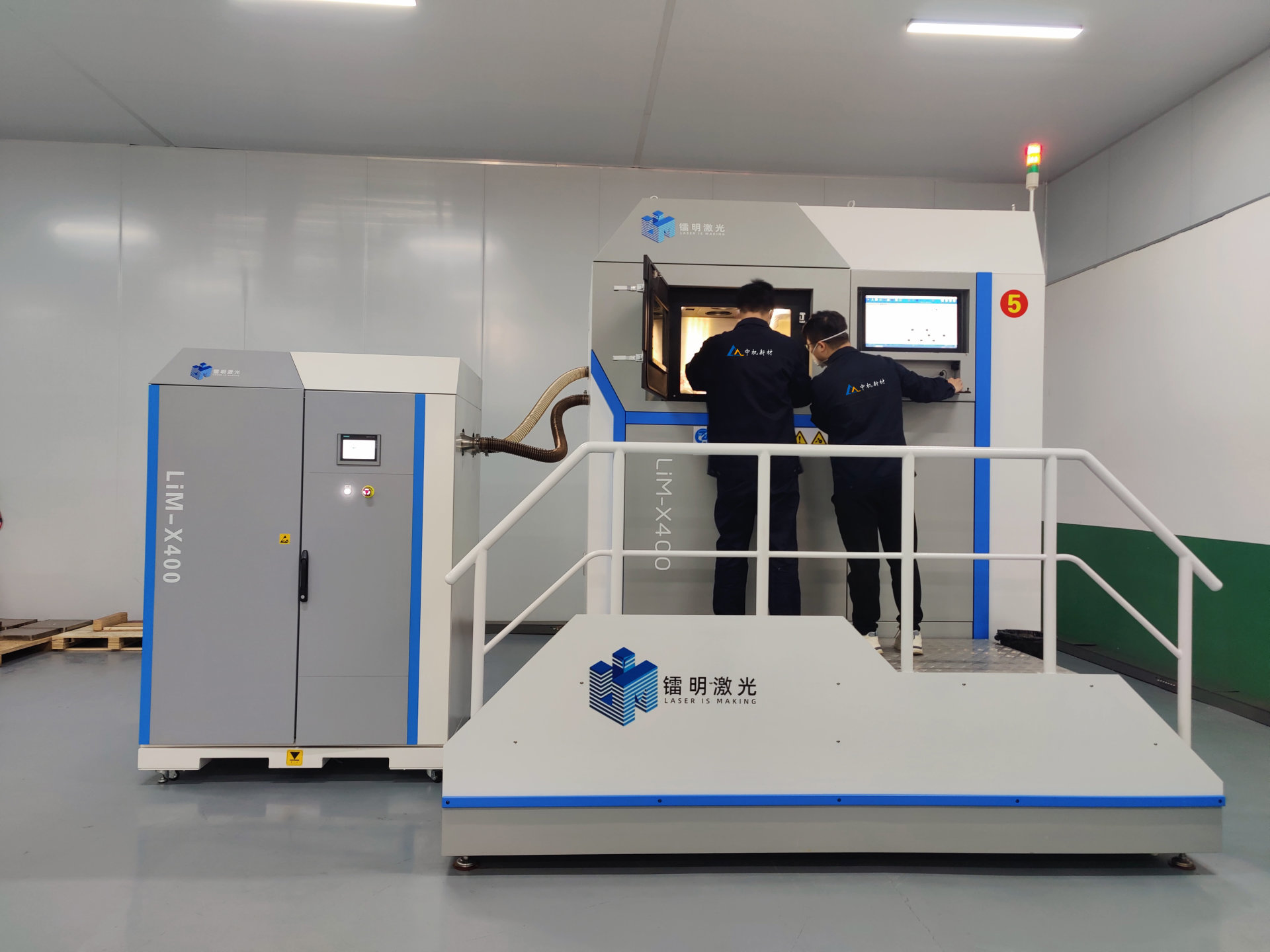

Multiple laser equipment purchased by Zhongji New Materials

Laser Metal 3D Printing Equipment Promotes Verification and Innovation of Metal Powders

The importance of metal powder materials determines that they must undergo strict verification before application, and only materials that pass verification can ensure the various properties of the formed parts. In the past, Zhongji New Materials only tested the chemical elements, particle size, flowability and other indicators of metal powder materials in the laboratory, and could not verify the mechanical properties of formed products. Based on this demand, Zhongji New Materials purchased LiM-X400 series 3D printing equipment from Laser and has achieved the verification of material formed products in the laboratory.

Zhongji New Materials uses a laser 3D printer for material verification

According to Fan Bin, the General Manager of Zhongji New Materials, "Previously, before the metal powder left the factory, due to the lack of 3D printing equipment, it was impossible to obtain the final mechanical properties of the powder's morphology, processing state, etc. Therefore, it was necessary to deliver the material to the customer and determine the material properties based on the feedback of the customer's printing results.". In this case, due to factors such as different processes and parameter settings during the printing process, there may be slight differences in the particle size distribution, flowability, and other data of the powder, making it difficult for us to confirm its accurate state. The 3D printing equipment of Tianjin Laiming Laser Technology Co., Ltd. (hereinafter referred to as "Laiming Laser") helps us pre validate the powder. Before the powder is delivered, 3D printing is used to form samples, verifying the stability and printing effect of metal materials, providing assurance for batch use of materials After the introduction of 3D printing equipment, the process of material verification is advanced before the materials leave the factory, greatly improving the efficiency of material research and development, and also playing an effective role in promoting the application of new materials. At present, many grades of materials such as high-temperature alloys and titanium alloys have been well validated on the LiM-X series of laser 3D printing equipment.

Samples printed by laser 3D printer for Zhongji New Materials

A professional after-sales team and a comprehensive training mechanism to alleviate customer concerns

After the equipment was sold, Radiant Laser provided comprehensive product training and on-site explanations, helping customers quickly grasp the operation and maintenance of the equipment. While communicating face-to-face with customers, it also helped them solve problems encountered during the 3D printing process, ensuring stable operation of the equipment. Mr. Fan from Zhongji New Materials mentioned, "After purchasing the equipment for the laser, three engineers provided us with long-term equipment debugging and operation training. We didn't leave until we fully mastered the operation method of the equipment. In the later printing process, regardless of any problems encountered, the technical personnel of the laser also provided us with corresponding solutions at the first time. They were very professional and dedicated."

Laiming Laser has a strong after-sales team. Fast, accurate, thoughtful, and thorough are the after-sales principles that Luming Laser always adheres to. Laser customer service personnel are on standby 24 hours a day, constantly monitoring changes in customer needs and product satisfaction. They always adhere to the principle of effectively solving customer problems, ensuring worry free purchasing for customers and establishing a good reputation.

The application fields of metal 3D printing are quite extensive, with many application scenarios in industries such as aerospace, automotive manufacturing, injection molding, and medical treatment. Many important components are completed through 3D printing, and mature and high-performance powder materials directly affect the success rate of finished product printing, and also to some extent affect the development of 3D printing technology. In the future, with the continuous research and application of new materials, 3D printing can be applied in a wider range of fields, thereby making 3D printing the main means of manufacturing, greatly promoting technological innovation and advanced manufacturing development.

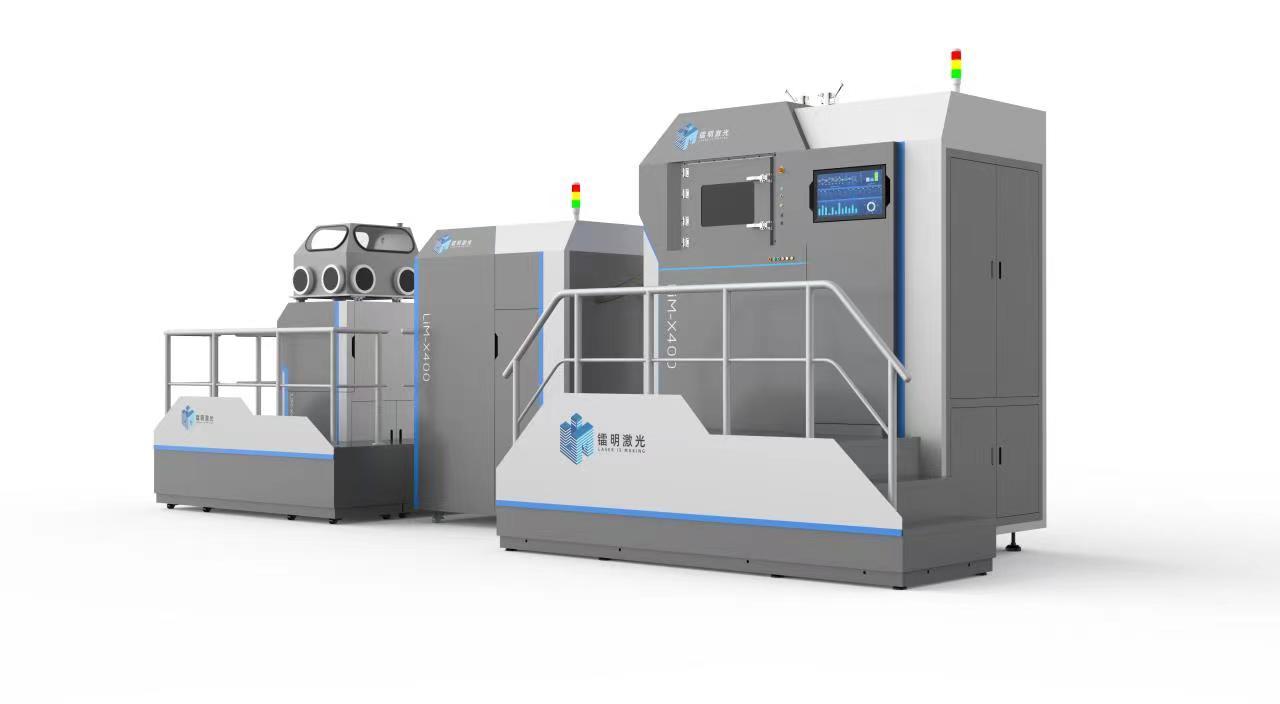

LiM-X400series

Forming size: 400mm x 450mm x 500mm (excluding substrate) (customizable) Printing accuracy: ≤ ± 0.1mm (XY)

Equipment advantages►

1. High reliability, all core components are sourced from domestic and foreign head suppliers, with high precision, reliable performance, high degree of equipment automation, convenient installation and debugging, and good human-machine interaction.

2. Efficient and stable, making outstanding innovations in forming efficiency, process optimization, and smoke and dust filtration, reducing inert gas consumption, adopting a permanent filtration system, without the need to replace the filter element.

3. Safety protection, using printing and powder cleaning with multi station conversion, full process safety protection, reducing the contact between operators and powder, and strictly ensuring the cleanliness of the equipment usage environment.

4. Comprehensive solutions, providing solutions from raw materials and powder processing to processing technology, process analysis, and post-processing methods.

function characteristics►

1. The standard processing size of the LiM-X400 series selective laser melting equipment is 400mm x 450mm x 500mm and provides multiple laser systems. The LiM-X400 series of universal laser melting equipment has become a high-performance equipment due to its large production space and laser technology. The extremely rich basic equipment and extensive configuration selection enable application oriented device configuration.

2. Use software Magics RP and module Support GeneratorSG+, as well as slicing software SLM Build Processor, to process and generate machining files. Can download and edit data formats used in professional fields.

Metal 3D printing

Related Articles

Market Activity