Education Research Solutions

Education and Research

Education Scientific Research解决方案

Overview

In recent years, there are more and more intelligent manufacturing and additive manufacturing majors in middle and higher vocational education and undergraduate education in China. Metal 3D printing manufacturing process research, material application development, and talent training colleges and universities are an indispensable force. Through the mode of school-enterprise cooperation, Radium Laser has jointly built a research and development platform, carried the support carrier for the transformation of scientific and technological achievements, and built a technological innovation system combining "production, study and research" with enterprises as the main body, so as to optimize the environment for talent introduction and education and promote the rapid development of "production, study and research" cooperation.

undefined

Technical advantages

Personalization

Tailored, multiple iterations in one loop

High Efficiency

Complex structure integrated forming, efficient batch production

Process Traceability

Real-time monitoring record of key parameters

Lightweight

Optimize structural design, take into account product performance while achieving part weight reduction

Talent Cultivation

Integration of production and education, directional cultivation

Help Scientific Research

Subject research, equipment assistance

Application Case

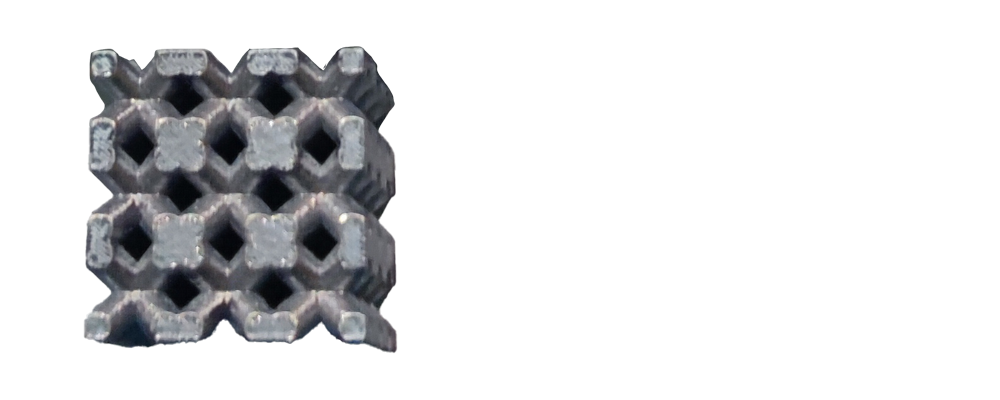

Lattice optimization structure

A model rotates the tail

Recommended Equipment

Related News