Hebei University of Science and Technology Magnesium Alloy-Metal 3D Printing Customized Equipment, Tianjin LiM Laser has been successfully delivered

Author: LiM Laser

Time:2023-05-15

Magnesium alloy has the characteristics of low density, high specific strength, high specific stiffness, excellent damping performance, good thermal stability and electromagnetic radiation resistance, good conductivity and thermal conductivity, and good process performance. Its unique physical and chemical properties make it play an important role in high-end manufacturing fields such as civil aerospace and automotive medical applications. However, at the same time, magnesium alloys have disadvantages such as poor corrosion resistance, easy oxidation and combustion, poor mechanical properties at room temperature, and poor heat resistance. Therefore, research on additive manufacturing of magnesium alloys requires extremely strict requirements for equipment safety and process stability. Based on this, the Laser team conducted extensive experiments and repeated adjustments and optimizations to meet user needs, and successfully delivered the LiM-X260E series magnesium alloy customized equipment to Hebei University of Science and Technology. This is also another successful attempt by Laser to explore school enterprise cooperation in depth.

Hebei University of Science and Technology to buy the LiM laser LiM-X260E series of equipment

Assisting research projects and recognizing the advantages of customized product development

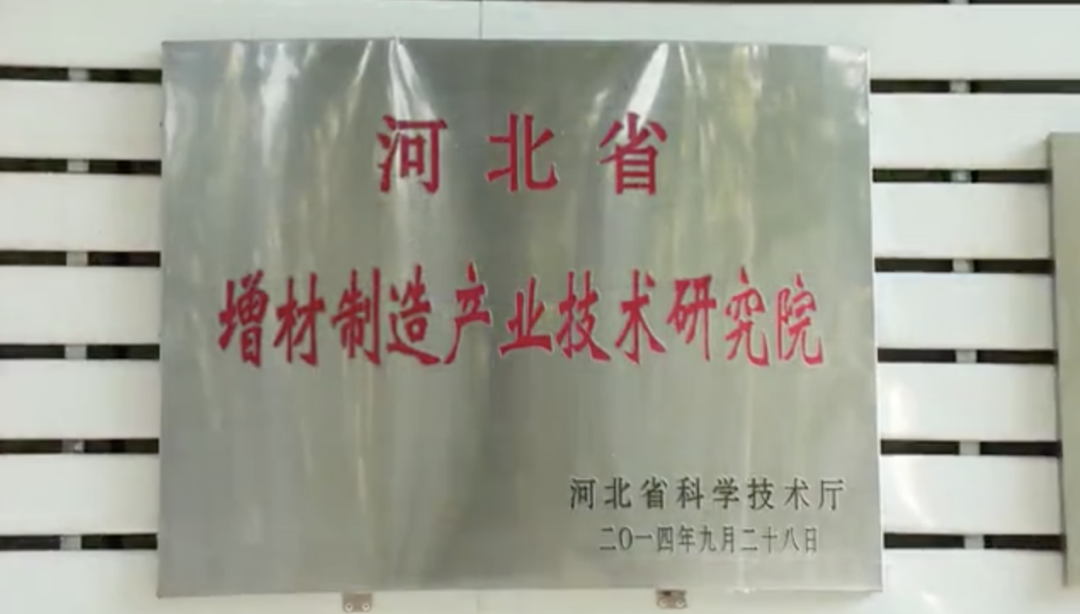

The LiM-X260E series equipment delivered by the laser to Hebei University of Science and Technology will be put into research and application at the Hebei Additive Manufacturing Industry Technology Research Institute. At present, the research institute hopes to achieve 3D printing of large-sized magnesium alloy components to assist in the research and manufacturing of civil aerospace structural components. However, traditional equipment has low scanning speed and power, making it difficult to produce efficiently. The research institute originally hoped to produce magnesium alloy specialized equipment through independent research and development, but there were shortcomings in some aspects, so it chose to jointly build and develop with the enterprise. After extensive understanding and in-depth communication, Radiant Laser stood out in the development of customized products and reached a cooperation agreement with the school. In order to efficiently complete magnesium alloy related projects, the school and research institute have put forward the following requirements for this customized equipment: the mechanical structure of the equipment can be improved and upgraded; Require the software control system to open secondary development permissions, such as adding monitoring of the forming process, melt pool, and wind field in the later stage; Ensure that the control system has independent intellectual property rights, etc. In response to these needs, a dedicated team was formed by Laser to carry out customized design, debugging, and ultimately complete acceptance.

Complete acceptance of LiM-X260E series equipment

Hebei Additive Manufacturing Industry Technology Research Institute is a technology collaborative innovation platform jointly built by Hebei University of Science and Technology, multiple backbone enterprises in the field of additive manufacturing, relevant universities, and research institutes in 2014. The research direction covers the entire 3D printing industry chain, including research and development of additive manufacturing equipment and its industrialization, additive manufacturing material preparation technology and its industrialization, additive manufacturing forming process technology research and application, personalized medical technology research and application of additive manufacturing, etc

At the beginning of the establishment of Hebei Additive Manufacturing Industry Technology Research Institute, domestic metal 3D printing technology was still in the initial stage of development, so foreign brand equipment was given priority in introduction. However, in practical use, it is often limited by factors such as service, region, and international situation. With the rapid development of related technologies in China, the research institute is turning its attention to domestic brands. The cooperation reached with the school and research institute this time can be said to be another affirmation of the products, technology, and services of Radiant Laser. It also inspires the Radiant Laser team to continuously leverage its technological advantages, focus on user needs, and achieve technological innovation and breakthroughs. The relevant person in charge is also full of expectations for the follow-up cooperation between LiM Laser and Hebei University of Science and Technology and Hebei Additive Manufacturing Industry Technology Research Institute. They hope that the two sides can strengthen cooperation in scientific research: jointly apply for research topics, deepen cooperation to explore cutting-edge technologies, and produce results to promote technological industrialization.

Looking forward to school enterprise cooperation and promoting the application of technology in a wider field

Based on the resources of the Additive Manufacturing Industry Technology Research Institute, Hebei University of Science and Technology has been teaching basic forming principles and processes of additive manufacturing to students majoring in mechanical manufacturing and intelligent manufacturing engineering since 2014. It has also led some students to participate in research projects related to the institute and participate in scientific and technological competitions. In 2022, Hebei University of Science and Technology was approved to establish the "Additive Manufacturing Engineering" major. In terms of talent cultivation, the school hopes to not only cultivate students in this major, but also generate interest in additive manufacturing among students in neighboring majors, allowing this technology to continuously penetrate into various majors and integrate with each other.

LiM Laser also hopes to achieve school enterprise cooperation in professional education, jointly apply for projects with the school, cooperate with national level project research and development, jointly host competitions, etc., to achieve key common technology research and development, scientific and technological achievement transformation, and professional talent cultivation. We look forward to working with university users to jointly promote scientific research and innovation in the entire 3D printing industry chain, leverage the technological advantages of metal 3D printing, and explore new applications in new fields; Promote the application and development of industries such as civil aerospace and high-end healthcare; Accelerate the application pace in the civilian field, ultimately promote the innovation and iteration of metal additive manufacturing technology, and lead the high-quality development of the additive manufacturing industry.

Metal 3D printing

Related Articles

Market Activity