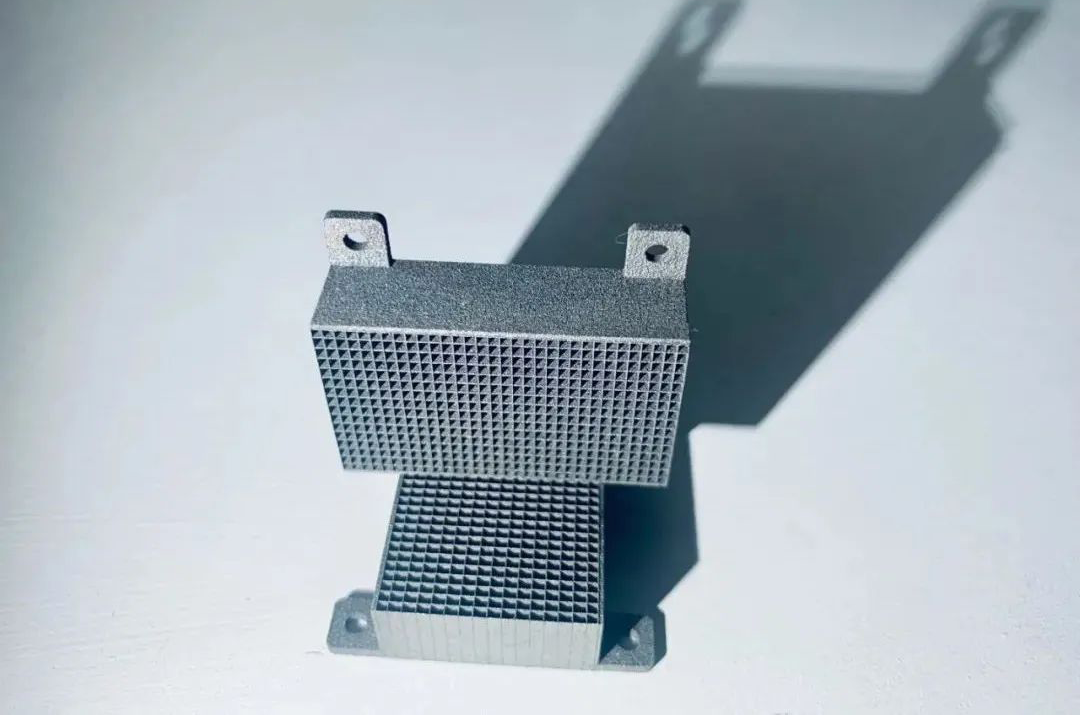

LiM-X150A Series

Application field:Civil Aircraft / Civil Aerospace / Education / Medical / Culture & Creativity

Elaborating and Striving, Pursuing for Excellence.

Check Price

Technical Parameters

|

Build Envelope |

Cuboid cabin:150mm×150mm×220mm Cylinder cabin:Ф140×180mm;Ф100×75mm;Ф80×75mm(Optiona) Incl. 20mm Substrate |

|

Variable Layer Thickness |

20 ~ 100μm |

|

Laser Power |

200W;500W |

|

Scanner |

High-speed Scanner |

|

Field Lens |

f-θ Lens |

|

Recoater |

Variable Speed Powder Recoater<One-way> |

|

Build Rate |

≥15cm³/h 200W Laser;≥30cm³/h 500W Laser |

|

Power Dissipation |

≤5kW |

|

Available Material |

Superalloy, Aluminum Alloy, Titanium Alloy, Stainless Steel, Die Steel, Tungsten Alloy, Cobalt Chromium Alloy, Etc |

undefined

Equipment Advantages

The circular cylinder equipment adopts a whole cylinder heat-ingform, and the preheating temperature can reach 500°C.

Self-developed software

Independent development stable operation

Intelligent monitoring

Powder bed monitoring module equipped

Long life filtration system

With backblow filter function, filter life time lasts more than 100,000 hours

Wide scenes and applications

Available within various working scenes less limitation

Related Cases

Related News

Related Products

Get a quote for a metal 3D printer

* Note: to get the price of metal 3D printer, please be sure to fill in the information accurately, and keep the communication smooth, we will contact you as soon as possible!