-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

LiM Laser power scientific research! Congratulations to the Institute of Mechanics for a key technological breakthrough in the research of high-fuel-rate solid-liquid engines!

Author: LiM Laser

Time:2022-02-14

Recently, the Institute of Mechanics of the Chinese Academy of Sciences (hereinafter referred to as the Institute of Mechanics) has made key technological breakthroughs in the research of single-hole-high-fuel-rate solid-liquid engines. For the first time in the world, a multi-stage construction and synergistic enhancement of metal composite solid-liquid engine fuel concept and molding method are proposed to revolutionize mechanical properties and combustion performance. Founded in 1956, the Institute of Mechanics is a comprehensive national-level mechanics research base established by Mr. Qian Xuesen's engineering science thoughts. It enjoys a high reputation in the international mechanics community and has made important contributions to my country's civil aerospace industry and national economic and social development. LiM Laser is very honored to be able to participate in this project and provide technical support for the project in the preparation of aluminum-based metal structures.

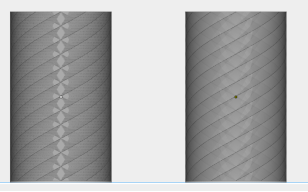

This time in the preparation of aluminum-based metal structure, LiM laser technicians after many discussions and parameter adjustment, through many rounds of debugging, successfully printed a satisfactory aluminum-based metal structure for mechanics.

Small forming Angle: the parts are spiral structure, the forming Angle is small, the internal support can not be added, increasing the difficulty of printing, thanks to the superb printing technology and rich operating experience of laser technicians, to promote the smooth printing of parts.

Clear secondary structure: the metal matrix is called the primary structure, and the spiral blade is called the secondary structure through structural modification such as drilling holes, and the spiral structure with small holes is formed once by 3D printing. It is mentioned in the paper that "especially the Al-B structure increases the Young's modulus by 1194% and the yield stress by 381.3%."

The core of high-quality development is technology leadership and innovation-driven, LiM Laser will adhere to the "quality first, customer first" business philosophy, adhere to technological innovation, with the spirit of craftsmanship grinding every product, excellence, to create China's metal additive manufacturing quality business card.

Related Articles

Market Activity