-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

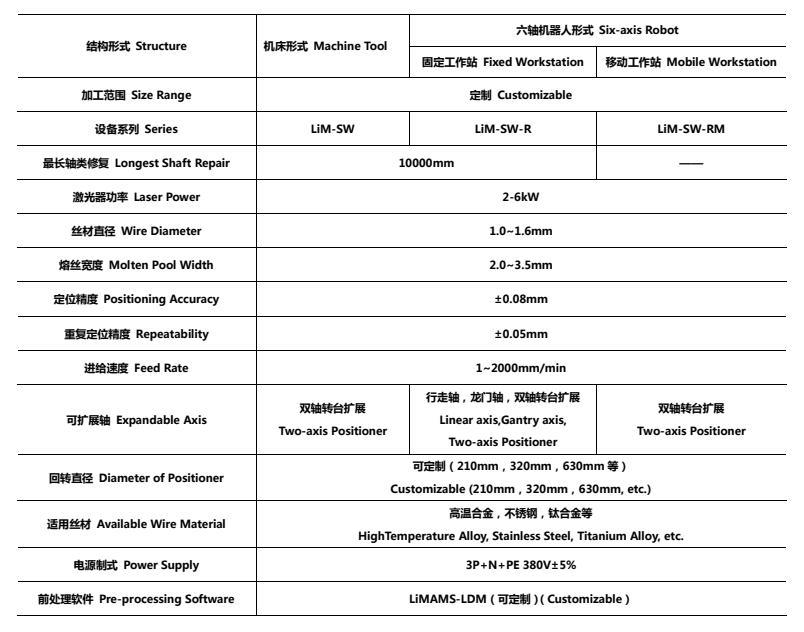

Technical Parameters

|

Structure |

Machine Tool |

Six-axis Robot |

|

|

Fixed Workstation |

Mobile Workstation |

||

|

Series |

LiM-SW |

LiM-SW-R |

LiM-SW-RM |

|

Longest Shaft Repair |

10000mm |

- |

|

|

Laser Power |

2-6kW |

||

|

Wire Diamete |

1.0~1.6mm |

||

|

Molten Pool Width |

2.0~3.5mm |

||

|

Positioning Accuracy |

±0.08mm |

||

|

Repeatability |

±0.05mm |

||

|

Feed Rate |

1~2000mm/min |

||

|

Expandable Axis |

Two-axis Positioner |

Gantry axis,Two-axis Positioner |

Two-axis Positioner |

|

Size Range |

Customizable |

||

|

Available Wire Material |

Titanium Alloy, Stainless Steel,HighTemperature Alloy, etc. |

||

|

Power Supply |

3P+N+PE 380V±5% |

||

|

Pre-processing Software |

LiMAMS-SW Customizable |

||

|

Available Wire Material |

Titanium Alloy, Stainless Steel,HighTemperature Alloy, etc. |

||

undefined

Equipment Advantages

Many years of experience in technology and research and development, supporting customers to customize equipment.

Self-Developed Software

Independent research and development of pre-processing software system, seamless compatible equipment.

Safe and Reliable

Equipment component selection, hardware and software design logic, production and processing process monitoring and other multi-dimensional to ensure the safety of operators, equipment, parts.

High Integration

The operating system is highly integrated, with centralized operation and unified monitoring of all subsystems.

Related Cases

Customer Case-Steel Industry Event Radium Laser 3D Printing Makes Baoshan Steel Equipment "Reborn"

Related News

Get a quote for a metal 3D printer

* Note: to get the price of metal 3D printer, please be sure to fill in the information accurately, and keep the communication smooth, we will contact you as soon as possible!