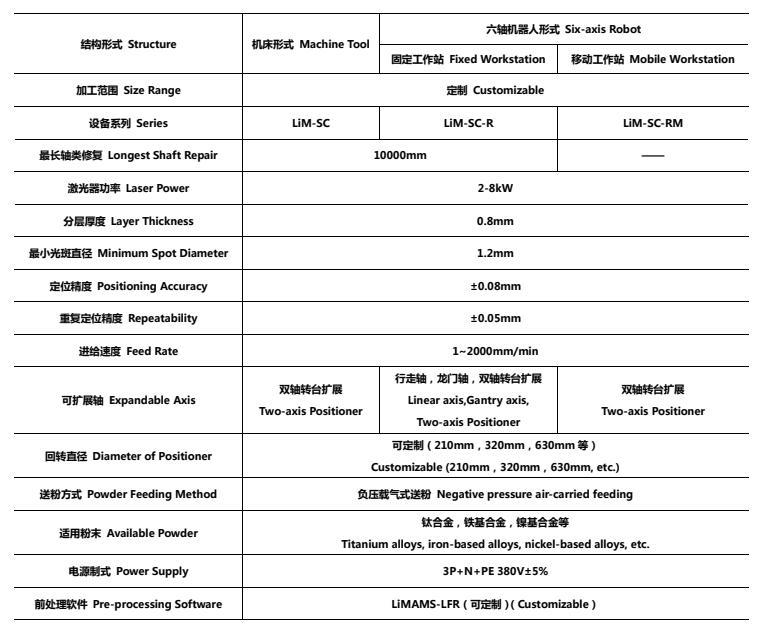

Technical Parameters

|

Structure |

Machine Tool |

Six-axis Robot |

|

|

Fixed Workstation |

Mobile Workstation |

||

|

Series |

LiM-SC |

LiM-SC-R |

LiM-SC-RM |

|

Longest Axis Repair |

10000mm |

- |

|

|

Size Range |

Customization |

||

|

Laser Power |

2-8kW |

||

|

Positioning Accuracy |

±0.08mm |

||

|

Repeatability |

±0.05mm |

||

|

Feed Rate |

1~2000mm/min |

||

|

Expandable Axis |

Two-axis Positioner |

Linear axis, Gantry axis,Two-axis Positioner |

Two-axis Positioner |

|

Diameter of Positioner |

Diameter of Positioner, Customizable 210mm,320mm,630mm |

||

|

Available Powder |

Titanium Alloy,Iron-based Alloy, Cobalt-based Alloy, Nickel-based Alloy , etc |

||

|

Power Supply |

3P+N+PE 380V±5% |

||

|

Pre-processing Software |

LiMAMS-SC Customizable |

||

undefined

Equipment Advantages

Independent research and development of pre-repair processing software.

Flexible Structure

Customize different structures and drive forms to cover most of the usage scenarios.

Safe and Reliable

Rigorous equipment selection, scientific integration, perfect interlock.

Service Support

Process support, comprehensive service, no worries.

Related Cases

Customer Case-Steel Industry Event Radium Laser 3D Printing Makes Baoshan Steel Equipment "Reborn"

Related News

Get a quote for a metal 3D printer

* Note: to get the price of metal 3D printer, please be sure to fill in the information accurately, and keep the communication smooth, we will contact you as soon as possible!