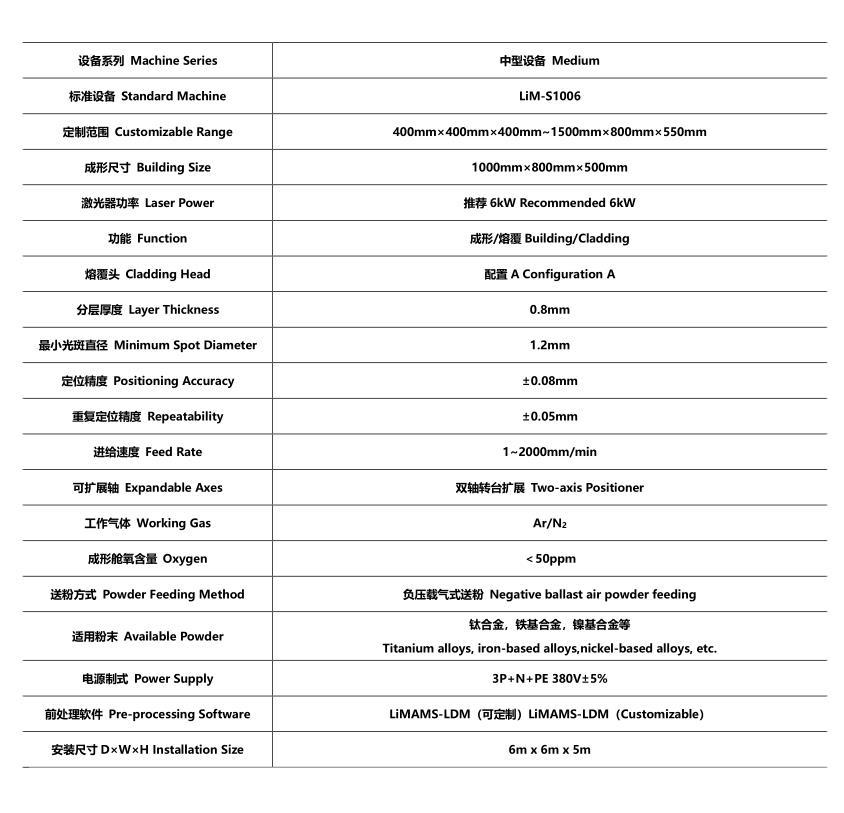

Technical Parameters

|

Customizable Range |

400mmx400mmx400mm ~ 1500mmx800mmx550mm |

|

Building Size |

1000mmx800mmx500mm |

|

Laser Power |

Recommended 6kW |

|

Cladding Head |

Midium and low laser power |

|

Minimum Spot Diameter |

1.2mm |

|

Layer Thickness |

0.8mm |

|

Positioning Accuracy |

±0.08mm |

|

Repeatability |

±0.05mm |

|

Feed Rate |

1~2000mm/min |

|

Expandable Axes |

Two-axis Positioner |

|

Available Powder |

Titanium Alloy,Iron-based Alloy, Cobalt-based Alloy, Nickel-based Alloy , etc |

undefined

Equipment Advantages

The core components such as powder feeder are fully designed independently; independent research and development of pre-processing software.

High Integration, Strong Plasticity

Optical, mechanical, dust purification, powder feeding and other major systems centralized operation, unified monitoring.

Excellent Quality, High Reliability

The selection of main components has been long-term actual use and process verification.

Safe Design, Worry-Free Operation

Perfect interlock function; safe and reliable filter element replacement device; professional laser protection function.

Related Cases

Customer Case-Steel Industry Event Radium Laser 3D Printing Makes Baoshan Steel Equipment "Reborn"

Related News

Related Products

Get a quote for a metal 3D printer

* Note: to get the price of metal 3D printer, please be sure to fill in the information accurately, and keep the communication smooth, we will contact you as soon as possible!