News, TSC-LiM Laser Application Projects were successfully selected into the list of the first batch of typical application scenarios of additive manufacturing.

Author: LiM Laser

Time:2022-08-08

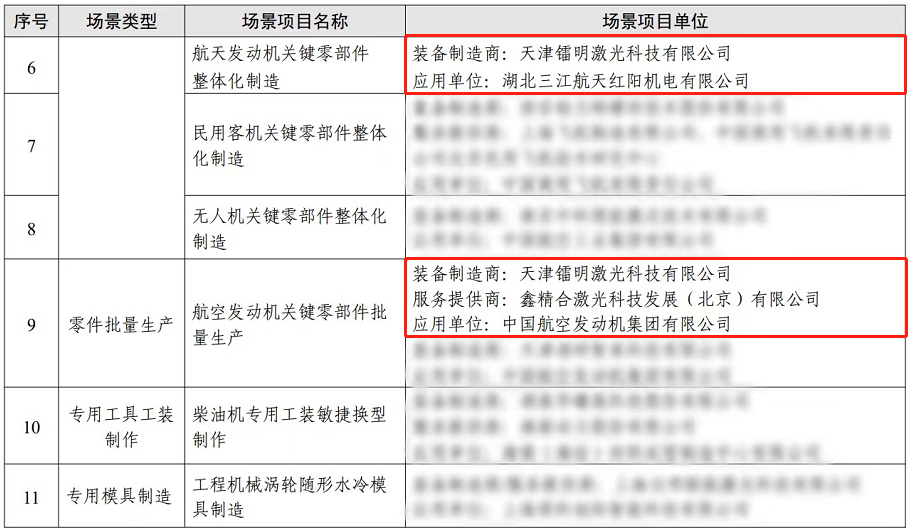

Recently, the Ministry of Industry and Information Technology announced the list of the first batch of typical application scenarios for additive manufacturing. The projects declared by TSC Laser Technology Development (Beijing) Co., Ltd. (hereinafter referred to as "TSC") and its subsidiary Tianjin LiM Laser Technology Co., Ltd. (hereinafter referred to as "LiM Laser") were successfully selected. TSC Cooperation provides solutions for China Aviation Engine Group Co., Ltd. in the project of "mass production of key components of aero engines.

As a professional manufacturer of metal 3D printing equipment, LiM Laser has provided Hubei Sanjiang Aerospace Hongyang Electromechanical Co., Ltd. in the "Integrated Manufacturing of Key Components of Civil Aerospace Engines" project in the application scenario of "Integrated Manufacturing of Complex Structure Products" The solution is provided for China Aviation Engine Group Co., Ltd. in the "Mass Production of Key Components of Aero Engine" project. "Mass production of parts" and "Integrated manufacturing of complex structure products" are both typical application scenarios of additive manufacturing. TSC has many years of experience in metal 3D printing service, while LiM Laser has always been committed to the technical research and development and innovation of metal additive equipment. In recent years, in order to meet the high requirements of the aero-engine industry for parts, LiM Laser has successively introduced multi-series metal 3D printing equipment, practice has verified the delivery of tens of thousands of metal 3D printing parts, which have been applied to various domestic engines, technically solving the problem of complex parts forming, promoting the mass production of complex parts, and contributing to the improvement of engine manufacturing technology in China.

Additive manufacturing technology has changed the traditional manufacturing method. With the development of metal 3D printing technology, additive manufacturing technology has been more and more successfully applied in the civil field. In order to meet the market demand, LiM Laser has continuously invested in technology research and development. At present, the company has independently developed more than 10 metal additive manufacturing equipment, which has continuously broadened the application scenarios of metal 3D printing, and enabled metal 3D printing to achieve more in the civilian field. Technical breakthroughs have brought customers higher product added value, reduced production and research costs, and increased product profits. At present, the series of LiM laser equipment has been widely used in ships, gas turbines, steel, construction machinery, automobiles, molds, education, medical treatment, cultural creation and other fields besides the civil aerospace field.

In the future, TSC will continue to exert its equipment and technical advantages in the field of additive manufacturing with its branches, provide new ideas for the manufacture of functional parts of complex metal structures, and continue to output broader industry application scenarios.

Additive Manufacturing, Metal 3D Printing

Related Articles

Market Activity