Limit size | successful printing 0.2 rod diameter typical parts

Author: LiM Laser

Time:2022-10-17

With the improvement of the performance and structural complexity of metal parts, the difficulty, cost and cycle of manufacturing by traditional processes such as casting and forging are increasing rapidly. Laser additive manufacturing technology with advanced technology and resource economy provides a new solution.

Laser additive manufacturing metal parts technology hasMeet the complex structure, near net shape high precision, excellent performance and other characteristicsIt can change the processing mode of traditional metal parts. It is one of the most promising application technologies for manufacturing complex precision metal parts, and it is also one of the key basic technologies supporting intelligent manufacturing in civil aviation, civil aerospace, medical and other fields.

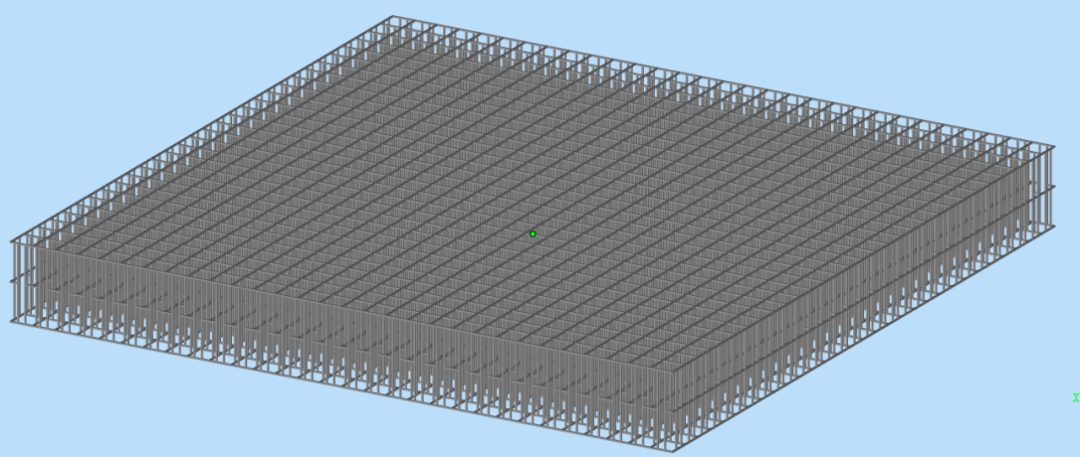

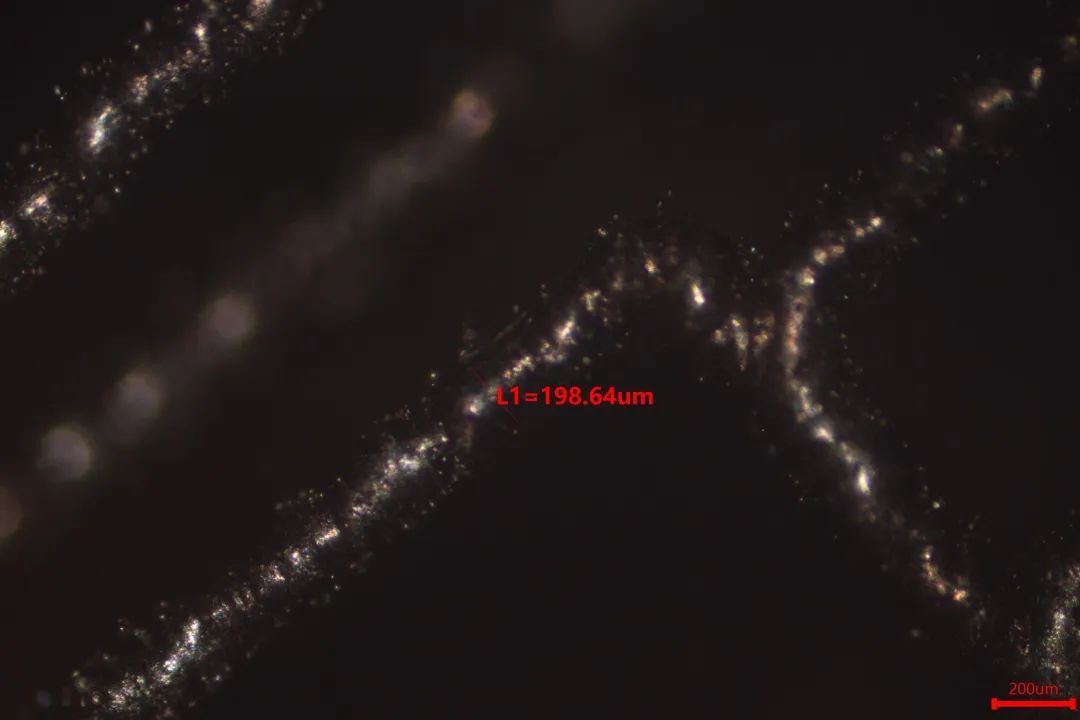

Based on the long-term observation of the market andMetal Additive ManufacturingRecently, the research and development team of LiM laser process successfully printed out the laser power, spot size, scanning strategy, scanning speed and other process parameters LiM-X260A by adjusting the laser power, spot size, scanning strategy and scanning speed of the self-research equipment.Aluminum alloy large area (150mm * 150mm) limit size structural parts, The overall structure of the formed parts is intact, and the thickness is uniform,The rod diameter is 0.2mm, and the rod diameter dimension accuracy reaches ± 0.025mm.

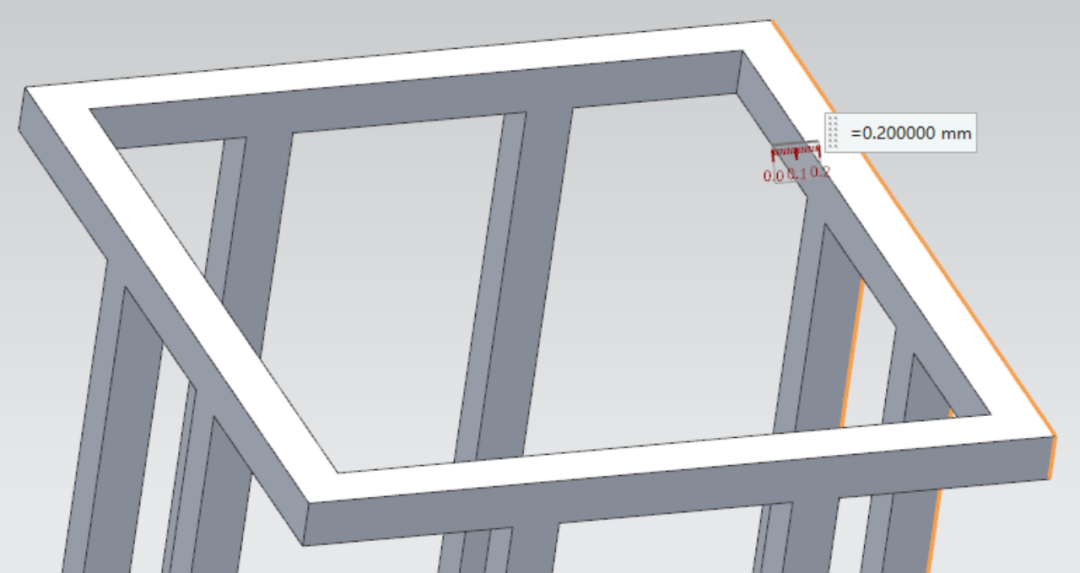

cell structure model

Print Model

The part has the characteristics of small rod diameter, low strength and fragility. The cross cell structure determines the growth direction of 45 degrees, resulting in easy ball formation at the dot matrix node, which is extremely difficult to form. The previous process can only meet the forming conditions of the minimum rod diameter of 0.4mm. LiM laser process personnelBy optimizing the forming process and breaking through technical difficulties, we have successfully LiM-X260A our self-developed equipment.On the realization of stable productionThe customer is highly satisfied with the finished part.

Partial Rod Diameter at 50 Magnification

This marks the greater possibility of deep integration of LiM laser equipment and research institute research and development, and LiM laser equipment and technology have once again entered a new height.

LiM-X260 SeriesIt is a customizable laser selection melting equipment introduced by LiM Laser after many product iterations and validations,Forming size is 260mm×260mm×430mm, the maximum forming efficiency of single laser is 30cm ³/h; The maximum forming efficiency of double lasers is 45 cm³/h.

LiM-X260 equipment

The use of independent research and development of LiMPCS equipment control software, through industrial computer control, to achieve the automation of equipment printing, the use of special motion control system and imported servo drive, great.Improve the accuracy and stability of the movement of the forming system and the powder laying system.Can carry out a variety of alloy materials printing research, such as titanium alloy, aluminum alloy, high temperature alloy, cobalt chromium alloy, copper alloy, etc.

LiM Laser will continue to practice and optimize, continuously explore the limit size forming process scheme and process parameters, and realize the printing of limit size structural parts of different materials such as titanium alloy and superalloy on large equipment such as LiM-X400 series, LiM-X600 series and LiM-X800 series, so as to provide customers with the best part process scheme, continuously give full play to the advantages of metal additive manufacturing technology, provide more possibilities for manufacturing and create "limit possibilities".

Metal Additive Manufacturing

Related Articles

Market Activity