-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

User case... Radium laser helps aerospace Sanjiang Hongyang company to promote the upgrading of additive manufacturing technology.

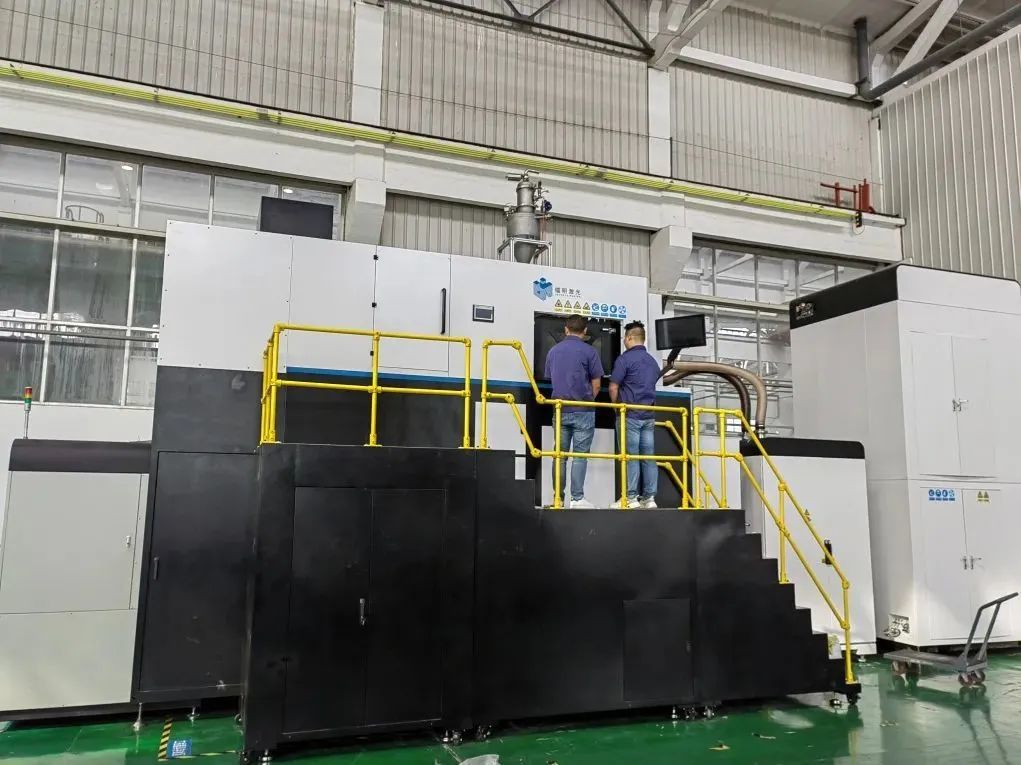

At the end of May this year, the radium laser LiM-X650H equipment was successfully offline and put into use in Hubei Sanjiang Aerospace Hongyang Electromechanical Co., Ltd., which helped boost domestic production.Additive Manufacturing EquipmentR & D upgrade has positive significance.

Hubei Sanjiang Aerospace Hongyang Electromechanical Co., Ltd. is affiliated to China Aerospace Science and Industry Group Co., Ltd. After years of development, the company has formed a technical system dominated by product structure design, final assembly and adjustment, composite materials, special connection molding, precision machining, performance testing and testing, etc., and has become a complete range of specialties, mass production and series R & D A modern high-tech enterprise with manufacturing capabilities.

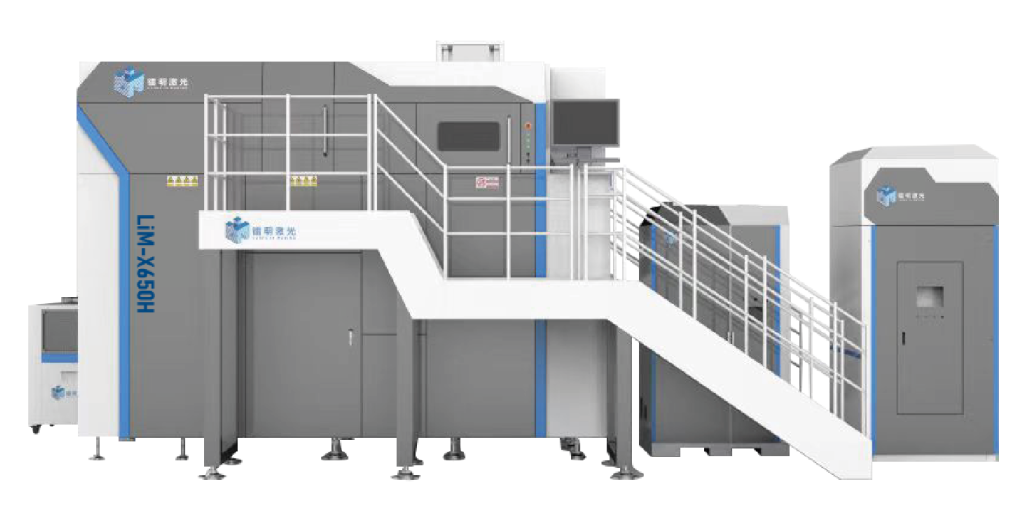

The LiM-X650H equipment delivered this time can meet the needs of additive manufacturing of large-size parts and can be widely used in aviation, aerospace and other fields.

LiM-X650H equipment

LiM-X650H Equipment Highlights

- The self-developed patented gantry dual-drive structure is adopted to improve the printing height and reduce the overall height of the equipment. The height of the equipment is 4.5m, which has good operability and maintainability;

- Equipped with a complete closed-loop powder automatic conveying system, the whole process of parts printing does not require manual intervention in the powder loading and unloading and screening process, and is equipped with a parts powder cleaning and recycling module, which is efficient, practical and safe.

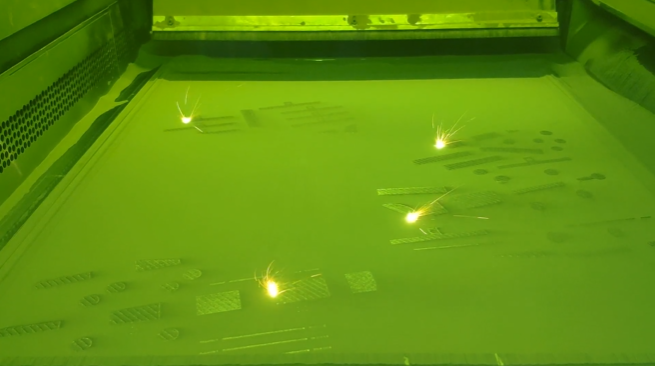

After the LiM-X650H equipment was put into use, Hongyang Company printed the structural parts with complex internal flow channels efficiently through a large number of process research, simulation and model optimization design. The internal flow channels had high dimensional accuracy, roughness met the design requirements, and uniform wall thickness. After testing, all indexes met the requirements, and the maximum height record of Hongyang Company's 3D printing was refreshed to nearly 1.5m. The successful development of meter-grade large components has brought Hongyang Company to a new level in the application of additive manufacturing technology.

The cooperation between Radium Laser and Hongyang Company, on the one hand, can meet the research and development and manufacturing needs of Hongyang Company in the aerospace field of large components, realize the integrated design and molding manufacturing of large complex structural parts, accelerate the research and development iteration of its product models, and help Hongyang Company to develop with high quality.

On the other hand, for radium laser in-depth understanding of user needs, verification of large-format gold.Additive manufacturing equipmentThe application and promotion of metal additive manufacturing equipment upgrade iteration is of positive significance. In the future, the two sides will jointly promote the application and development of metal additive manufacturing technology.

Latest Developments

Market Activity