Civil Aerospace/Aerospace Solutions

Civil Aerospace Solutions

Civil Aviation/Aerospace解决方案

Overview

The level of civil aerospace manufacturing is a yardstick to measure a country's scientific and technological strength, and it also directly reflects the development level of human technology. The products are composed of millions of parts, with a wide variety and complex structure, which have high requirements for stability, safety, light weight and refinement. Based on this, the design and manufacturing of various parts have extremely high process requirements and quality standards. Metal 3D printing technology can fully meet the needs in terms of complex structure forming, lightweight design, and shortening the production cycle. The backbone of the rapid development of the civil aerospace manufacturing industry.

undefined

Technical advantages

High Efficiency

Shorten the development cycle and reduce the cost of research and development.

High Efficiency

Complex structure integrated molding, efficient batch production

High Quality

Digital production, reduce product defect rate, high product precision, stable quality

Personalization

Can be customized according to demand, design more free

Lightweight

Structural optimization design, taking into account product performance while reducing the weight of parts.

Sustainable Development

Higher material utilization, reduce waste and achieve sustainable development

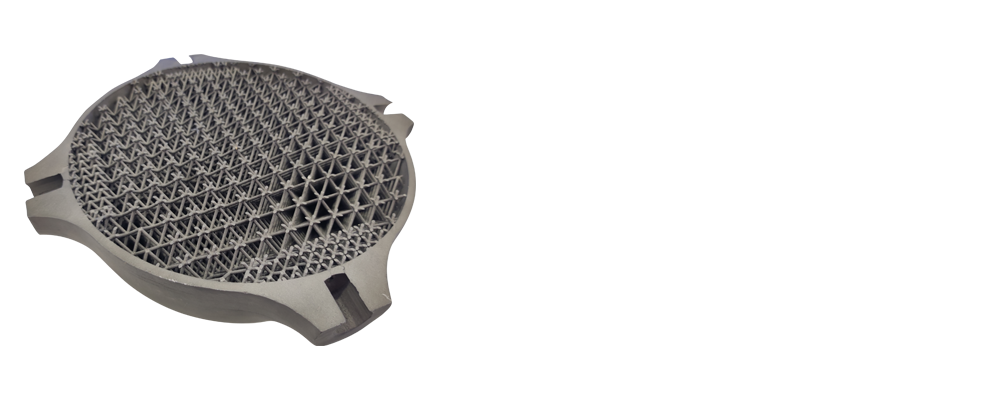

Application Case

Aeroengine exhaust assembly

Space Station Node Ball Planer

Recommended Equipment

Related News