TSC and LiM Laser appeared at the 7th China Space Power Joint Conference, focusing on the latest application results of metal additive manufacturing in the field of space power.

Author: LiM Laser

Time:2023-05-11

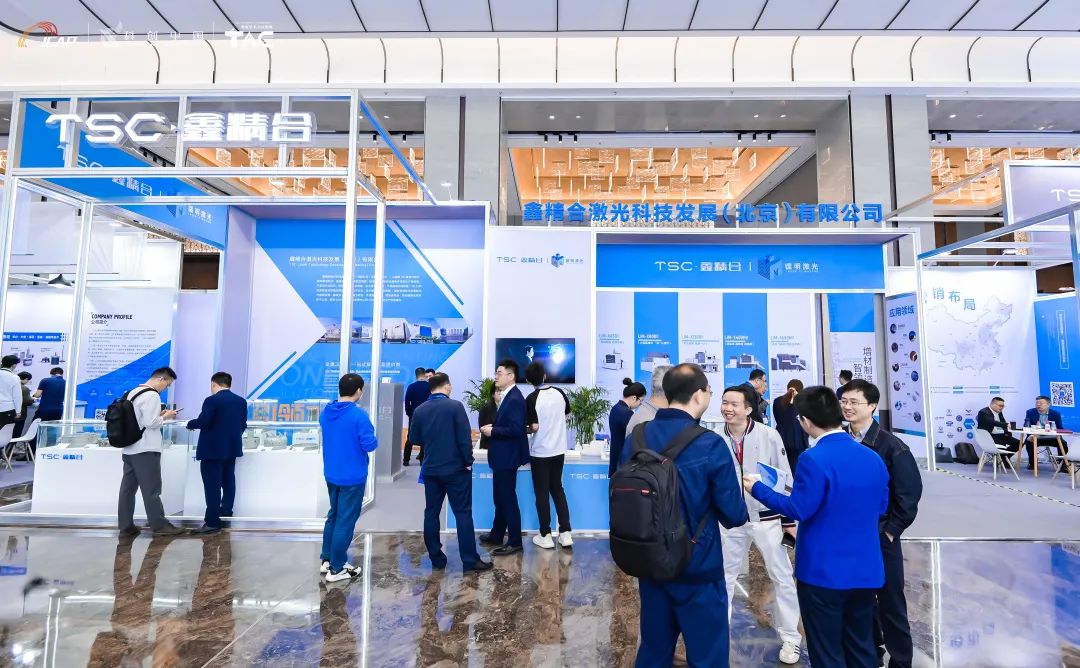

From May 10 to 12, the 7th China Space Power Joint Conference was held in Suzhou. The theme of this conference is "spanning the sky, strong power, integration and exchange". At the same time, a series of activities will be held, such as the 7th air space power joint conference, the 7th air space promotion technology exhibition, and the second air space power supply and demand docking conference. Focusing on the manufacturing of metal additive materials in the field of space power, TSC and its subsidiary LiM Laser participated in this meeting and exhibited the latest application results in the field of space power.

Space to promote technology exhibition, industry innovation application results show

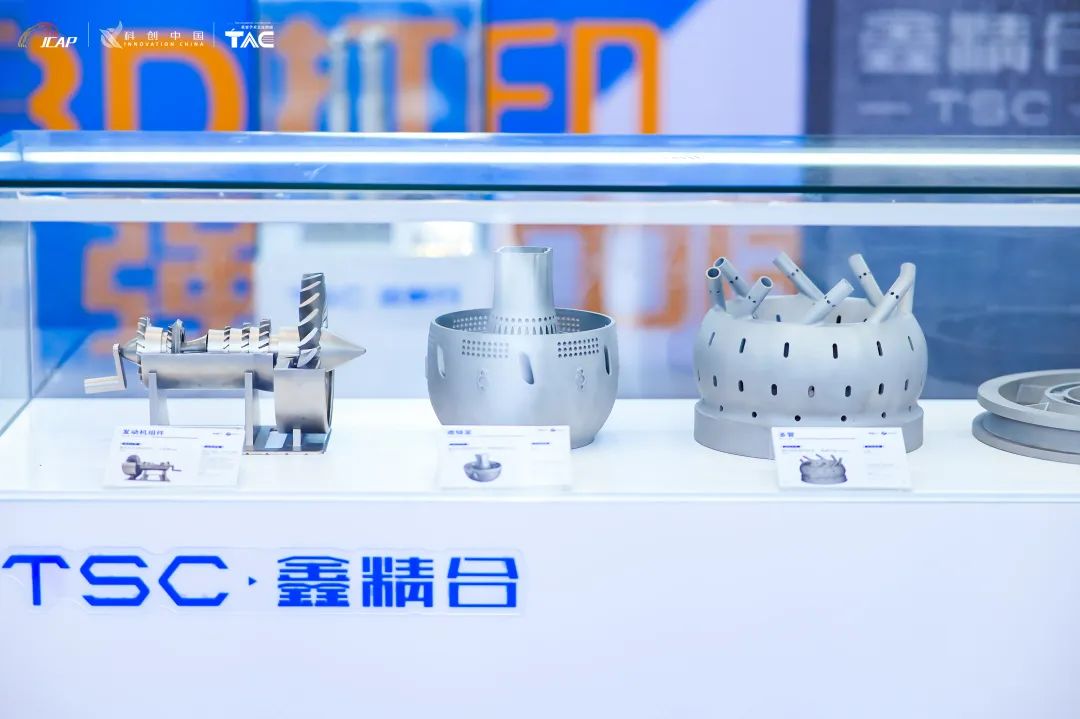

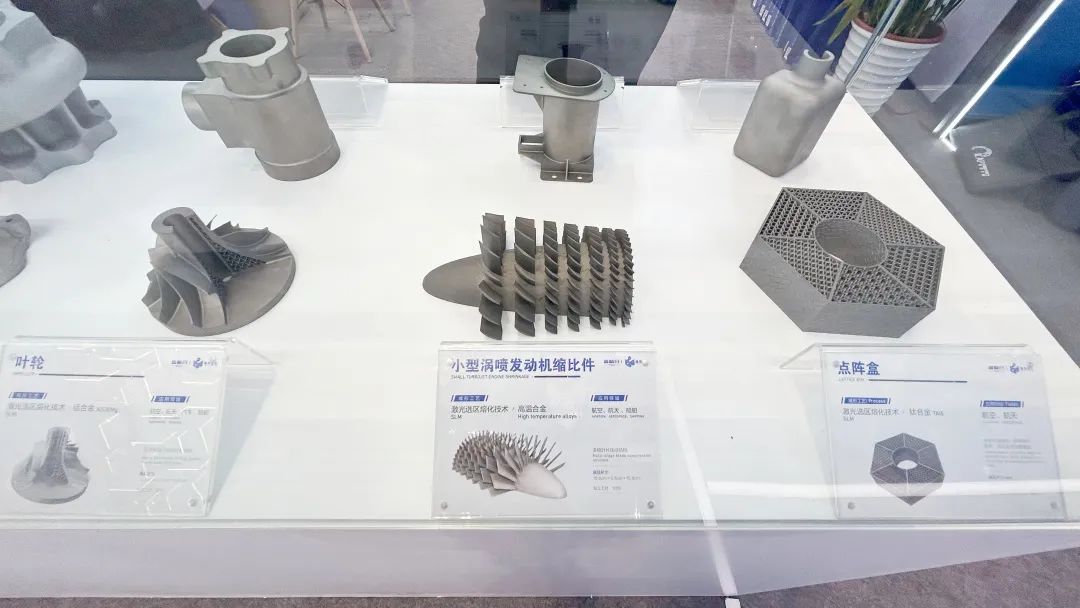

As an important part of the conference, the space propulsion technology exhibition opened at the same time. TSC-LiM Laser exhibited the latest application results of high-precision large-size metal 3D printing technology in the field of space power.

For example, the engine components manufactured in sections by laser selective melting technology realize the visualization of the complex internal structure of the engine. Combustion chamber with complex thin-walled structure; Multi-tube with complex sandwich structure formed integrally by metal 3D printing equipment, etc......

From left to right are engine components, combustion chamber, multi-pipe

The exhibition broughtMetal 3D printingThe exhibition covers the application cases of civili anaerospace, energy power, industry and other industries, and shows the advantages of metal 3D printing technology.

TSC-LiM Laser Booth received extensive attention from the audience and stopped to learn about the current situation of relevant technologies and industrial development.

Air and space power supply and demand docking conference, aggregate advantage resources hand in hand.

Zuo San is Li Guangsheng, founder and general manager of TSC

On May 11, the launching ceremony of the second air space power supply and demand docking conference was held, attended by Li Guangsheng, founder and general manager of Xin Jinghe. On May 12, Qi Haihao, sales director of TSC, gave a special speech at the supply and demand docking conference, introducing in detail the principle of metal 3D printing technology and its applicable scenarios to representatives of various enterprises, universities and scientific research institutes, and sharing the technical advantages, equipment advantages and industry cases of Xin Jinghe and its subsidiaries in the industry.

Qi Haihao, Sales Director of TSC

TSC Cooperation is a one-stop solution provider for metal 3D printing. This time, we participated in the supply and demand docking conference, hoping to accurately meet the needs of upstream and downstream enterprises in the civil aerospace industry and realize cross-border resource integration. Relying on its strong scientific research capability and rich industry experience, TSC-LiM Laser will continuously enhance the manufacturing and printing service capabilities of metal 3D printing equipment, provide innovative solutions for the production and manufacturing of users in the field of space power, and play an active role in accelerating the construction of a strong country in space.

Space-Space Power Joint Conference, Topic Sharing and Exchange Application Research

On May 12, the 15 sub-forums of this session were held in parallel, and representatives of TSC & LiM Laser shared the theme at three of the sub-forums. At the civilian Aviation Gas Turbine Propulsion Technology Forum, Guan Kai, General Manager of LiM Laser, delivered a keynote speech on "Research on Application of Additive Manufacturing in civilian Aviation Gas Turbine Propulsion Technology". Zhou Lingfeng, General Manager of Xi 'an Xin Jinghe, shared "Application and Prospect of Additive Manufacturing Technology in Liquid Propulsion Industry" at the Liquid Propulsion Technology Forum. At the sub-forum of advanced manufacturing and intelligent manufacturing technology, liu Bin, vice president of Xin Jinghe Technology, shared the theme of "Application and Prospect of Additive Manufacturing Technology in Space Power System.

Guan Kai, General Manager of LiM Laser

Zhou Lingfeng, General Manager of Xi 'an TSC

TSC Technology Vice President Liu Bin

TSC-LiM Laser will continue to carry out research and development and innovation of metal additive manufacturing technology, and work together with colleagues to provide more metal 3D printing solutions for the civil aerospace field and contribute to the high-quality development of China's civil aerospace industry.

Metal 3D printing, metal additive manufacturing

Related Articles

Market Activity