3D Printing Pioneer Makes Production Simpler | LiM Laser Appears in CIMT2023

Author: LiM Laser

Time:2023-04-18

On April 15, the 18th China International Machine Tool Exhibition came to an end. As a national high-tech enterprise, LiM Laser made its debut with intelligent production line solutions, providing new solutions for various manufacturing industries and fully demonstratingMetal 3D printing technologyThe application cases in various high-end manufacturing fields are highly concerned by domestic and foreign exhibitors.

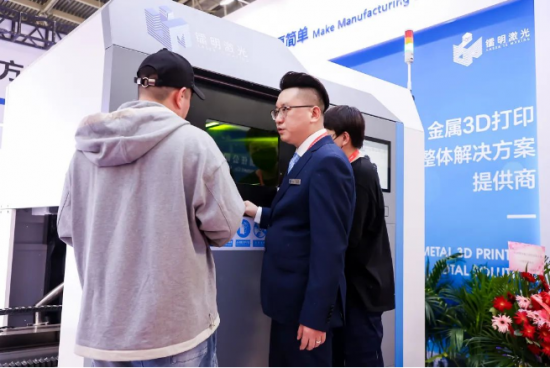

Intelligent production line solutions Shining Appearance

The W2-B213 booth where LiM Laser is located exhibited a LiM-X400 series of equipment and printed on the spot, attracting many domestic and foreign customers to stop to watch and exchange understanding. This series of equipment can be set up intelligent production line, through the conveying system and powder processing station will be a number of equipment in series, to achieve efficient, automated batch production. This intelligent production line solution is another important innovation achievement of LiM Laser's insistence on independent research and development, innovative manufacturing, and industrialization of cohesion.

At the same time, LiM-X260A series of equipment and some exhibition pieces appeared in the booth of Hong Kong Lifeng Group, which was also attracted by the audience.

Industry Application Cases Wonderful presentation

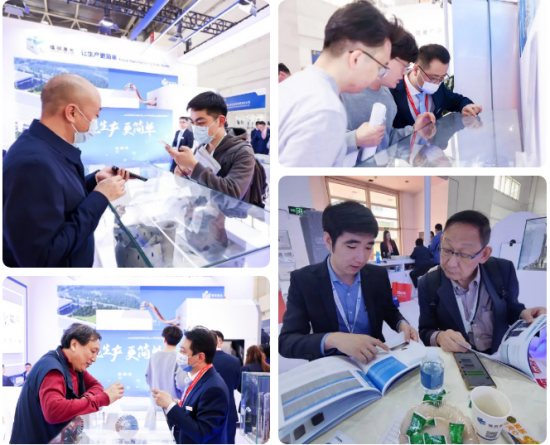

In this exhibition, LiM Laser also showed the application cases of civil aerospace, automobile, industry, medical treatment, mold and other industries for the guests, and patiently introduced the details of the exhibits to the audience, so that the guests can have a deeper understanding of metal 3D printing technology and the technological advantages of LiM Laser.

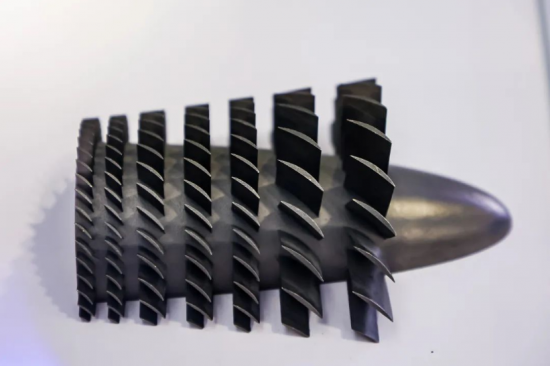

Metal 3D printed engine components, used in automotive and Marine fields, are made of stainless steel 316L material and fabricated in segments using laser selective melting technology to visualize the complex internal structure of the engine.

Metal 3D printing small turbojet engine reduction parts, multistage blade compression structure, mostly used in civil aviation, civil aerospace, Marine fields.

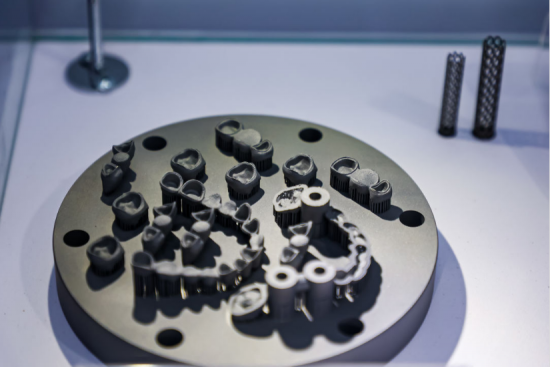

Metal 3D printed volute, with a complex internal flow path structure, is mostly used in the civil aerospace field.

Metal 3D printing denture, the material is cobalt-chromium alloy, fully reflects the application of metal 3D printing technology in the medical field, to achieve personalized, customized, rapid tooth customization.

Industry Media In-depth access coverage

During the exhibition, professional media such as Antarctic Bear, MM "Modern Manufacturing", China Industrial News, Jung Industrial Media, China Machinery, Civil Aviation Manufacturing Technology and other professional media came to LiM Laser one after another to conduct in-depth exchanges and on-site interviews on intelligent production line solutions.

Guan Kai, General Manager of LiM Laser, interviewed by Antarctic Bear

Li Guangsheng, General Manager of TSC, Accepts Interview with China Industry News

Guan Kai, General Manager of LiM Laser, Accepts Interview with MM "Modern Manufacturing"

Guan Kai, General Manager of LiM Laser, Accepts Interview with Metal Processing

LiM-X800 Series Equipment China Metal Processing Industry Innovation Product Award

MM "Modern Manufacturing" magazine held the "19th China International Metal Processing Summit Forum" at the same time as the exhibition, and held the "MM AWARD China Metal Processing Innovation Product Award" award ceremony. The LiM Laser LiM-X800 series equipment won the award. It is also another recognition of the company's innovation ability.

On-site activities blessing Gathering popularity

In this exhibition, the interactive activity of the lucky turntable set up by LiM Laser at the scene received enthusiastic participation from the audience. everyone lined up to participate and walked into the booth to learn about metal 3D printing technology.

First prize metal 3D printing Chinese dragon award-winning audience

Adhering to the concept of "making production easier", LiM Laser hopes to empower the traditional manufacturing industry with metal 3D printing technology and promote the digital and intelligent transformation and upgrading of the manufacturing industry. In the future, LiM Laser will still be deep plowing thick metal 3D printing field, with technological innovation to explore unlimited possibilities. The CIMT2023 has ended, the next exhibition, we continue to meet amazing!

Related Articles

Market Activity