Self-developed Selective Laser Melting Equipment Monitoring System to Escort the Forming Quality of Parts

Author: LiM Laser

Time:2023-05-24

Laser selective melting technology has high printing accuracy and has been widely used in civil aerospace, energy and power, automotive manufacturing, mold and other fields.

Large and complex structural parts require equipment to continuously print for a long time without interruption. During the continuous printing process, problems such as powder dropping/stacking, insufficient powder spreading, part warping, and powder bed scraping can easily cause serious problems such as incomplete fusion, excessive remelting, collision between parts and scrapers, and burning black spots, which can affect the printing effect. In response to the above issues, Laser has independently developed a laser selective melting equipment monitoring system, which can detect the printing status in real time, providing strong support for the long-term stable operation of the equipment.

The monitoring system can perform calculations based on the scanned and powder spreading status images, obtain information on the powder spreading status and printing area, and provide real-time feedback. At the same time, the detection threshold is adjusted to set the warning/shutdown area and the number of defects. The system automatically marks the defects and performs targeted processing. In addition, it also has a high-precision automatic grafting function, which can automatically identify the position of the part base, match slice information, and achieve automatic grafting printing.

Introduction to Common Options/Powder Distribution Monitoring System

Detection settings: The number of skip layers can be set to prevent incomplete powder coverage of the substrate surface from affecting the detection.

Define threshold: Set detection warning and shutdown parameters, and trigger shutdown when defects exceed the alarm value; If it does not exceed, identify the defect location and type, and provide a warning.

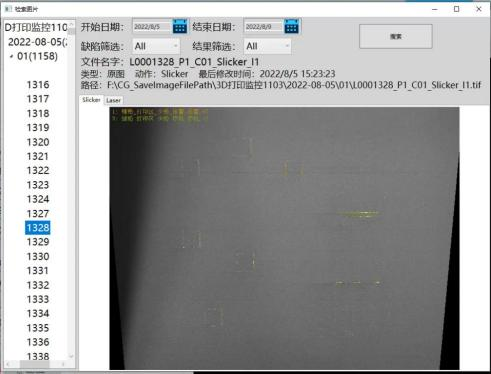

Image retrieval: The detection results and original images of each layer after powder coating and scanning are retained during printing, and can be quickly searched within the software.

This feature has the following characteristics: retrieval by time, traceability of images for each layer of all parts; Prompt and label the types of defects in the image, which can be enlarged to observe details; Mark different types of defects separately.

Introduction to detectable defect types/Powder spreading monitoring system

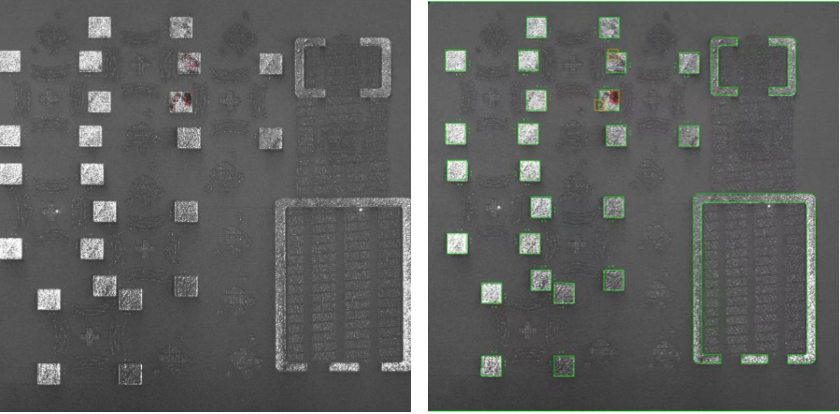

The detection system automatically identifies and distinguishes the printing area from the non printing area. If there are defects, they are marked and prompted; For different degrees of defects, equipment takes different disposal actions, such as patching, warning, and alarm.

Defect detection of the state after powder spreading

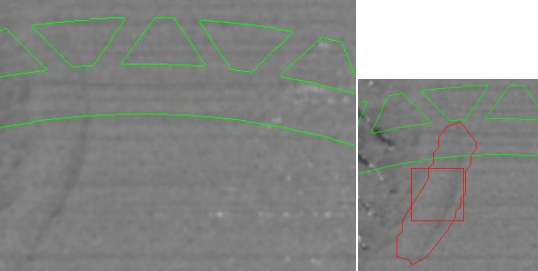

Multi powder detection in printing area: accuracy can reach 1mm ² , The green section represents the printing product area

Multi powder detection in printing area: accuracy can reach 1mm ² , The green section represents the printing product area

Multi powder detection in printing area: accuracy can reach 1mm ² , The green section represents the printing product area

Multi powder detection in printing area: accuracy can reach 1mm ² , The green section represents the printing product area

Printing area lifting detection: accuracy can reach 1mm ²

Printing area lifting detection: accuracy can reach 1mm ²

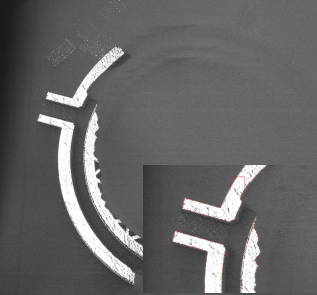

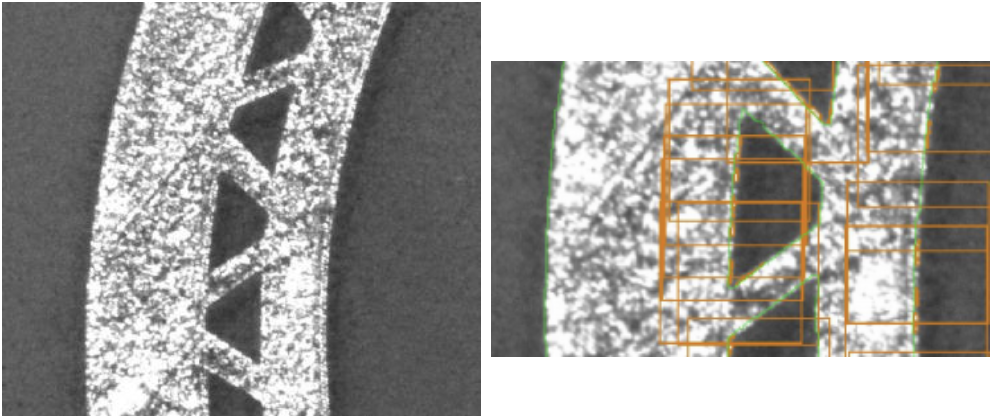

Printing area scratch detection: The scraper width detection accuracy can reach 0.5mm

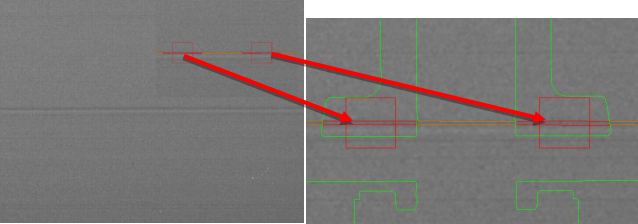

Printing area scratch detection: The scraper width detection accuracy can reach 0.5mm

Defect detection in scanned state

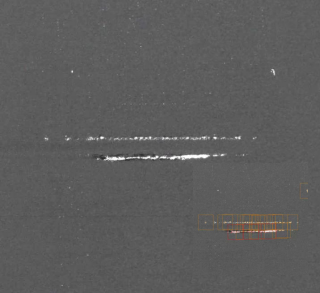

Black spots in the printing area: detection accuracy can reach 1mm ²

Black spots in the printing area: detection accuracy can reach 1mm ²

Part skewness detection in the printing area: with an accuracy of up to 0.5mm

Part skewness detection in the printing area: with an accuracy of up to 0.5mm

LiM laser selective melting equipment monitoring system independently developed by Laiming Laser has been verified. As a domestic metal 3D printing equipment manufacturer, we will always adhere to high-quality manufacturing, continuously innovate industrial technology, enhance competitiveness in various links, and provide customers with higher quality solutions.

Related Articles

Market Activity