Heavy market: multi-laser, large format, high size can be customized selective laser melting LiM-X400H series equipment.

Author: LiM laser

Time:2020-12-18

LiM laser long-term3D printing equipmentIndependent research and development and market observation, that China's market development for large-format, high-precision metal 3D printing equipment market demand is growing, since the LiM laser LiM-X150A, 260A, 400A series of equipment into the market to obtain a good installation rate and market response. However, the standard forming size of the LiM-X400H that has entered the market today is 450mm X 450mm X 1500mm, which is launched by the research and development team of LiM laser equipment based on the research on the characteristics of a large number of high-size parts and the iterative verification of equipment. LiM-X400H is not only a piece of equipment, but also a set of integrated solutions around the forming of large-format, high-size and high-precision parts provided by LiM laser for users, covering equipment, raw materials, auxiliary supplies, process parameters to software, post-processing and quality testing and certification are a series of supporting services.

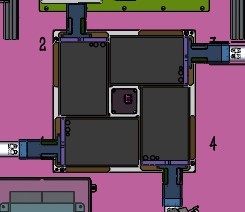

LiM-X400H Equipment

The LiM-X400H continues the full opening and customizability of X series equipment. The 450x 450x 1500mm standard forming size adopts IPG500W × 4 fiber laser, Scanlab × 4 high-speed galvanometer and SIL f-θ × 4 field mirror, which can realize a layer thickness of 20-120 microns, greatly improving the printing efficiency, and at the same time solving the problems of many process variables in the forming process and the inability to quantify and control the forming quality, the modular design of the X series makes the forming chamber, powder dust removal system, electrical system and software system can be flexibly configured to meet different needs of personalized customization.

LiM-X400H optical system

■ 4 sets of laser and imported optical system to achieve 4 galvanometer sintering at the same time, speed up the printing speed;

■ The use of the world's highest quality brand of optical accessories, to achieve low loss, high precision optical system;

■ Optimize the system selection scheme to achieve 80 ~ 100μm precision high-energy spot, improve printing accuracy and surface gloss of parts;

■ Ensure the stability of the molten pool, ensure the ultra-low porosity inside the parts, and improve the quality of the parts.

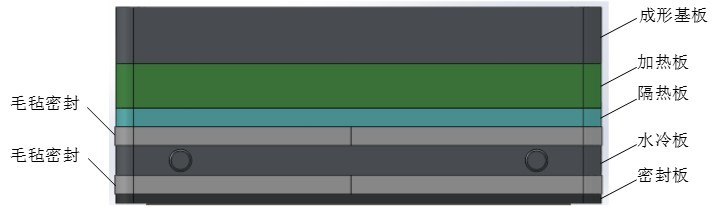

LiM-X400H forming system

■ Double screw synchronous drive, to ensure the stability of the substrate when printing high depth parts without deformation;

■ The dual-drive system has applied for a unique invention patent number;

■ With the famous international brand grating ruler, the accuracy of the forming system reaches 0.005mm;

■ Double-layer felt sealing layer to solve the problem of powder leakage;

■ The use of heating plate, heat insulation plate and water cooling plate can not only ensure the preheating of the substrate, but also effectively isolate the influence of heat on the mechanism, so that other parts are always in a constant temperature state;

■ The heating plate adopts dual-channel heating to ensure uniform heating and accurate temperature control.

LiM-X400H powder spreading system

■ Double linear module drive, simple structure, easy installation, higher precision;

■ The scraper is a double scraper structure, which can realize two-way powder spreading, shorten the printing cycle or double scraper one-way powder spreading, so that the printing layer thickness of the parts is more uniform;

■ The use of special tooling can be used to level the forming substrate with the help of the scraper reference frame, which can greatly improve the quality of the first layer of powder laying parts, thus improving the sintering effect;

■ Scraper can replace rubber scraper, brush scraper and steel scraper.

LiM-X400H monitoring system

■ Double camera monitoring is adopted in the printing process, and a high-definition camera can shoot the powder spreading effect and printing effect each time, which is convenient for later analysis;

■ A high-definition camera can record the whole printing process in real time, which is convenient for remote monitoring and storage of video.

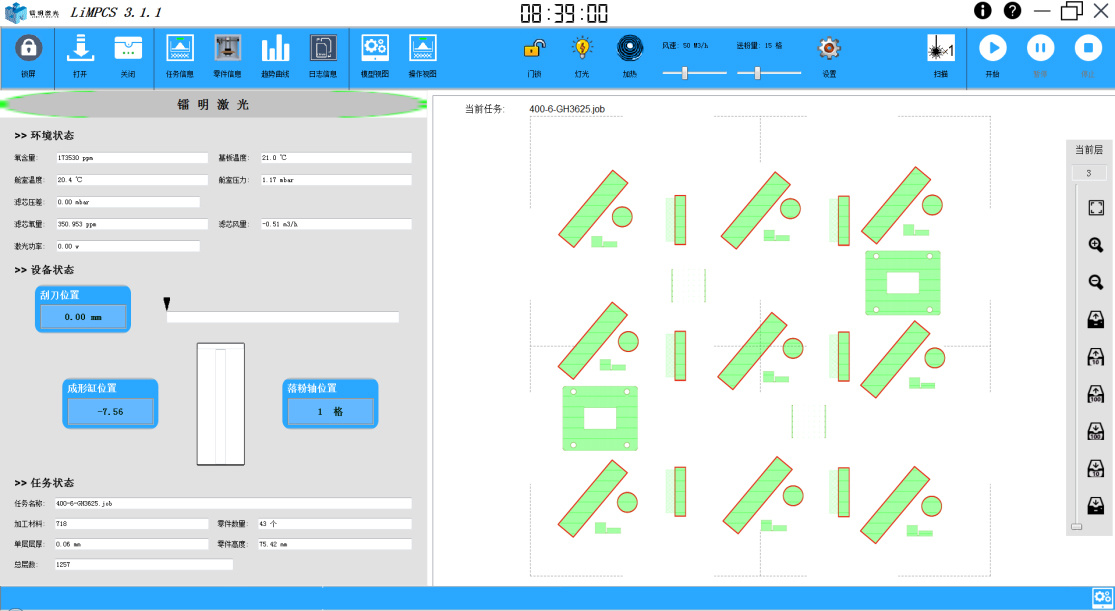

LiM-X400H control software

■ Using self-developed equipment control software, stable and efficient control of each part of the equipment, and accurate and timely feedback of the equipment status for the operator, so that the equipment is stable and safe operation;

■ Equipped with special motion control system and imported servo drive, which greatly improves the accuracy and stability of the forming system and the powder spreading system;

■ The introduction of model processing software Magics and BP from advanced global brands (Belgian Materialise) can optimize the processing of large and complex parts and provide absolutely reliable print files for subsequent printing.

3D printing equipment

Related Articles

Market Activity