LiM Laser LiM-X650H equipment won the 2022 metal processing industry-Jung technology innovation award

Author: LiM Laser

Time:2022-09-19

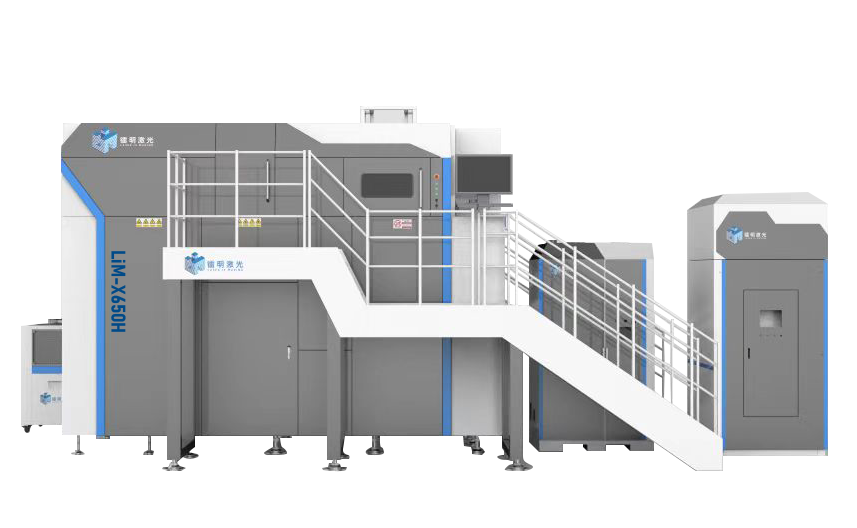

Recently, the LiM Laser SLM Additive Manufacturing Equipment LiM-X650H won the 2022 Metal Processing Industry-Jung Technology Innovation Award,Since its launch in 2021, this equipment is another honor after winning the second place in the "Top Ten Industrial Additive Manufacturing Equipment in 2021" selection in January 2022.

LiM laserLarge format, high sizeThe forming size of LiM-X650H equipment is 650mm × 650mm × 1680mm (including substrate), and 4. six lasers can be selected at the same time. Especially in terms of printing depth, it has reached the international leading level and has one of the highest levels of commercial sales of metal additive manufacturing equipment. The equipment structure adopts the LiM-X400H patented dual-drive structure successfully developed by LiM Laser, which realizes the gantry dual-drive structure and greatly reduces the overall height of the equipment. In the existing domestic and foreign laser selective melting equipment, the equipment with a forming width of more than 500mm x 500mm is using a single drive structure, according to the mechanical structure analysis and stability calculation, it is difficult to achieve the positioning accuracy of the forming cylinder within 5 m. The dual-drive structure adopts Siemens stable and mature control system, with double grating ruler, so that the positioning accuracy of the equipment can be stable within ± 5μm for a long time, providing customers with a stable and reliable drive control.

LiM Laser large format, high size LiM-X650H Equipment

Automatic powder conveying system

Large size parts printing cycle is long, with a large amount of powder, long cycle printing environment stability control is extremely important. The equipment is equipped with a complete closed-loop powder automatic conveying system. After adding powder, the equipment can automatically screen and dry the powder to reach the use state. During the printing process, the system efficiently and automatically completes the three processes of powder overflow recovery, powder overflow screening and powder supply. It works independently without affecting the printing of the forming chamber, and the powder collection and transportation efficiency reaches above 10L/Min. The whole process without manual intervention, to ensure the yield, efficient, practical and safe.

Security, stable and reliable

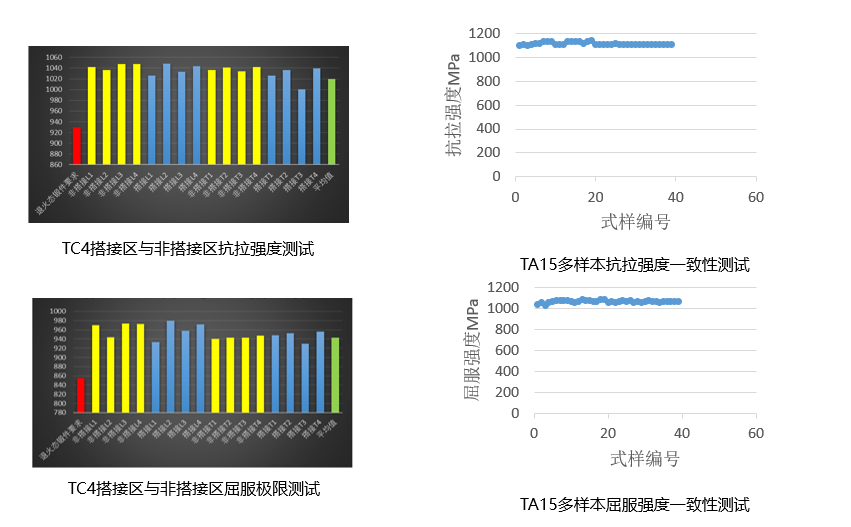

Mechanical property test

The minimum mechanical properties of multi-laser lap area shall not be less than 95% of the average value of single laser area; The consistency difference of mechanical properties of the whole width shall not exceed 5%; The tensile properties of nickel-based superalloy, high-strength aluminum alloy, titanium alloy, stainless steel and other materials are excellent in room temperature tensile test of standard sample rods.

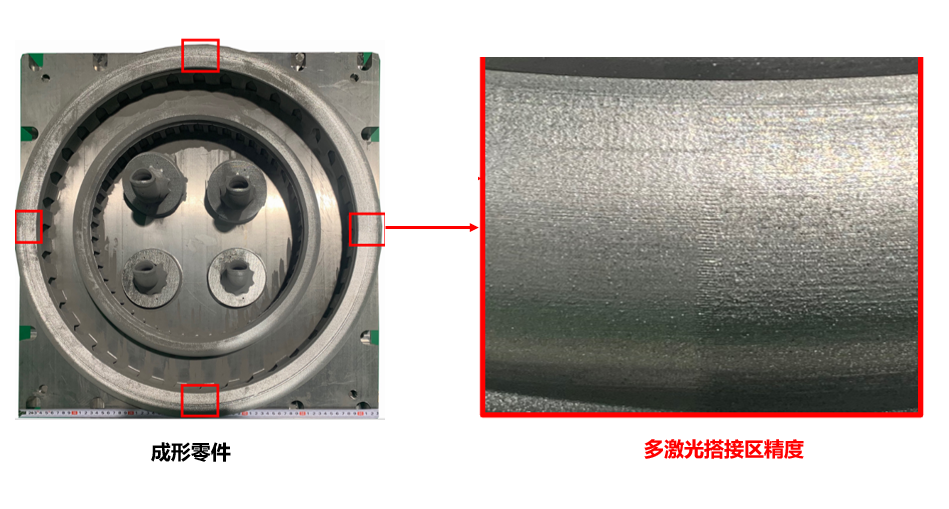

Multi-laser printing stitching area verification

LiM-X650H equipment can be applied to the integrated molding of complex structural parts in many fields such as aviation, civil aerospace, energy and power, automobile manufacturing, etc. At present, there are mature printing parameter packages for titanium alloy, superalloy, aluminum alloy and other materials. The equipment has excellent performance in forming efficiency, printing quality, use cost and other aspects. Many batches of complex structural parts such as complex structural rotary detonation components and isolation sections have been printed and verified.

Additive Manufacturing Equipment

Related Articles

Market Activity