-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

Perfect ending | LiM laser debut in DMC2023, enabling the development of precision mold manufacturing industry

Author: LiM Laser

Time:2023-06-14

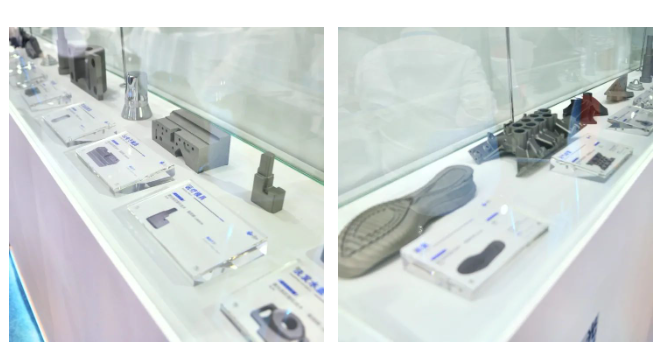

On June 14, the four-day DMC2023 China International Mold Technology and Equipment Exhibition came to a successful conclusion! This exhibition focuses on the high-quality development of the mold industry and the leadership of high-end equipment manufacturing technology, and displays high-end precision processing equipment and advanced mold manufacturing technology.

New products/shine

As a leading provider of overall solutions for metal 3D printing in China, the metal 3D printing technology, equipment and solutions presented at the DMC exhibition have attracted much attention, attracting all exhibitors to come and negotiate. Among them, the company's independent research and development of LiM-X400M equipment by the mold industry practitioners.

In the process of research and development of the equipment, the research and development team and benchmark customers in-depth discussion, fully considering the precision mold manufacturing on the forming quality, forming efficiency, production costs and other elements of the application needs, and finally formed a LiM-X400M equipment as the center of the mold industry special equipment, for mold users to improve quality and efficiency to provide assistance.

Consultation interaction/site hot

In this exhibition, the LiM laser team introduced application cases, in-depth communication technology and so on to each visiting audience with full spirit and enthusiastic and professional service. The on-site real-time printing of LiM-X260A equipment on display attracted more exhibitors and industry partners to stop and understand, consult and exchange.

Innovation is more than/the future can be expected.

Relying on its strong R & D strength, industry experience and strategic layout, LiM Laser will continue to strengthen technological innovation in the industry. With the help of the resources of this DMC exhibition, it will actively explore the application market of the mold industry, provide more end users with high-quality products and professional services, and jointly promote the high-quality development of the high-end mold manufacturing industry.

Related Articles

Market Activity