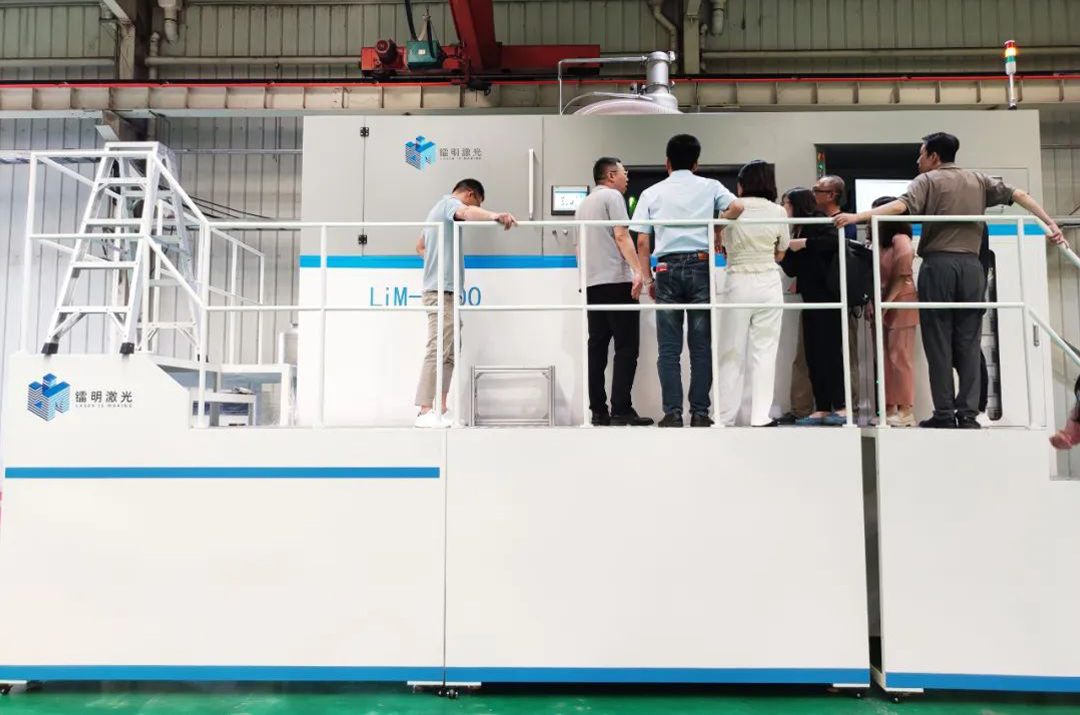

LiM-X800H+

Application field:Civil Aircraft / Aerospace

climb higher step by step, gathering upward force

Check Price

Technical Parameters

|

Build Envelope |

800mm×800mm×2620mm Incl. 120mm Substrate |

|

Variable Layer Thickness |

20 ~ 100μm |

|

Laser Power |

IPG 500W×6;500W×8;500W×10 1000W×6;1000W×8;1000W×10 |

|

Scanner |

Scanlab High-speed Scanner |

|

Field Lens |

Sill f-θ Lens |

|

Recoater |

Variable Speed Powder Recoater<One-way/Two-way> |

|

Build Rate |

≥150cm³/h Hexa Laser;≥200cm³/h Octa Laser |

|

Power Consumption |

≤ 45kW |

|

Forming Material |

Superalloy, Aluminum Alloy, Titanium Alloy, Stainless Steel, Die Steel,copper Alloy, Magnesium Alloy, Cobalt Chromium Alloy, Permalloy, Invar Alloy, Etc |

undefined

Equipment Advantages

The net forming height reaches 2500mm, breaking through conventional sizes and expanding printing space.

HIGH ACCURACY BUILDING PLATFORM

It adopts imported THK screw guide rail mechanism, and grating scale adjustment,which can realize positioning accuracy within ±0.005mm.

LONG LIFE FILTRATION SYSTEM

With backblow filter function, filter life time lasts more than 100,000 hours

Multiple Powder Recycling System

Automatic powder circulation system or split automatic circulation system can be independently selected according to demand

INTELLIGENT MONITORING

Powder bed monitoring module equipped

Related Cases

Related Products

Get a quote for a metal 3D printer

* Note: to get the price of metal 3D printer, please be sure to fill in the information accurately, and keep the communication smooth, we will contact you as soon as possible!