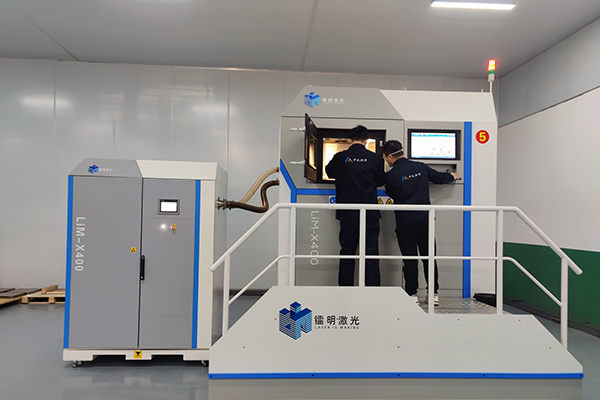

LiM-X400M+

Application field:3C Electron / Mold / Education / Medical / Culture & Creativity

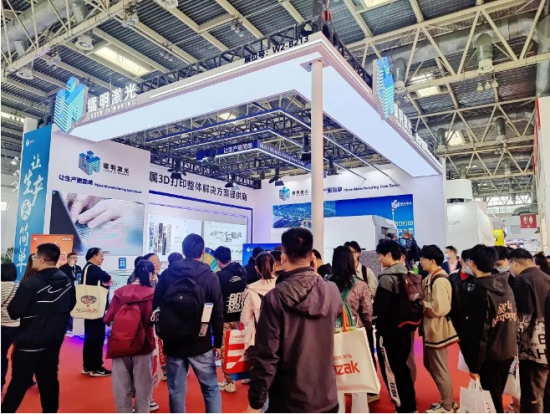

Boosting The Consumer Goods industry, Improve Quality And Efficiency.

Check Price

Technical Parameters

|

Build Envelope |

400mm×300mm×450mm;

Incl. 40mm Substrate |

|

Variable Layer Thickness |

20 ~ 100μm |

|

Laser Power |

IPG LiM-X400M/M+:500W×3 |

|

Scanner |

Scanlab High-speed Scanner |

|

Field Lens |

Sill F-θ Lens Domestic field mirrors can be selected |

|

Recoater |

Variable Speed Powder Recoater<One-way/Two-way> |

|

Build Rate |

35cm³/h-75cm³/h |

|

Power Dissipation |

≤9kW |

|

Available Material |

Superalloy, Aluminum Alloy, Titanium Alloy, Stainless Steel, Die Steel,copper Alloy, Magnesium Alloy, Cobalt Chromium Alloy, Permalloy, Invar Alloy, Etc |

undefined

Equipment Advantages

A variety of scanning strategies are used to segment a single part, so that the part can acquirediverse physical properties at a microsco pic level, improve performance dimensions, and therebyimprove printing quality.

Grafting process

Positioning, and printing, directly on the processed part base greatly simplifies the part coordinatemovement function and position verification method. A single person can complete the graftingpositioning work in a sh ort time on the spot and directly start the printing task, greatly shorteningdowntime and improvingequipment Utilization.

Breathable technology

Providing the third-generation breathable steel process, eliminating quality at the junction ofbreath able areas and dense eliminating,quality at the junction of breathable areas and denseareas, and greatly improving the overall yield rate of parts. Provide flexible and highly usablesolutions for mold trapped air.

Effective temperature control

The substrate temperature is set separately for different printing heights and different printingstages to effectively eliminate the stress and deformation caused by the structural characteristicsofthe product while ensuring smooth printing

Production quality management

Predictive maintenance is provided for the overload alarm of the overflow toner bucket, which isthe most co mmon problem in the printing, production process. Users can predict the time to cleanthe toner overflow bucket through the powder volume curve to avoid unexpected shutdowns

Related Cases

Related News

Related Products

Get a quote for a metal 3D printer

* Note: to get the price of metal 3D printer, please be sure to fill in the information accurately, and keep the communication smooth, we will contact you as soon as possible!