-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

Metal 3D printing makes it easier to manufacture complex flow patterns

Author: LiM Laser

Time:2023-02-17

In recent years, with the mature application of laser selective melting (SLM) technology, its advantages in producing complex flow pattern and pore structure parts have become increasingly apparent. This technology can avoid defects such as shrinkage porosity and porosity in traditional casting processes, and the part density can reach 99%.

Complex flow pattern pore structure parts printing display

The LiM laser uses self-developedLiM-X260 Series Selective Laser Melting EquipmentA typical piece of complex flow type pore structure is printed. The typical piece of pipe extends in all directions, staggered and complicated, and the inner diameter of each pipe of the part is different.The process team realized the smooth production of the part by adjusting the forming direction of the part and adding support appropriately. The inner surface roughness of the blank can reach Ra6.3μm. Through the post-treatment process such as abrasive flow, the inner runner roughness of the blank is further optimized.

Typical parts of complex flow pattern pore structure printed by LiM laser

Print display of horizontal hole structure

LiM laser also uses LiM-X260 series equipment to print the cross hole structure made of die steel, and its cross hole diameter is 10mm-20mm, which can still maintain good roundness.

Transverse hole structure of die steel material printed by LiM laser

Mold inner runner printing display

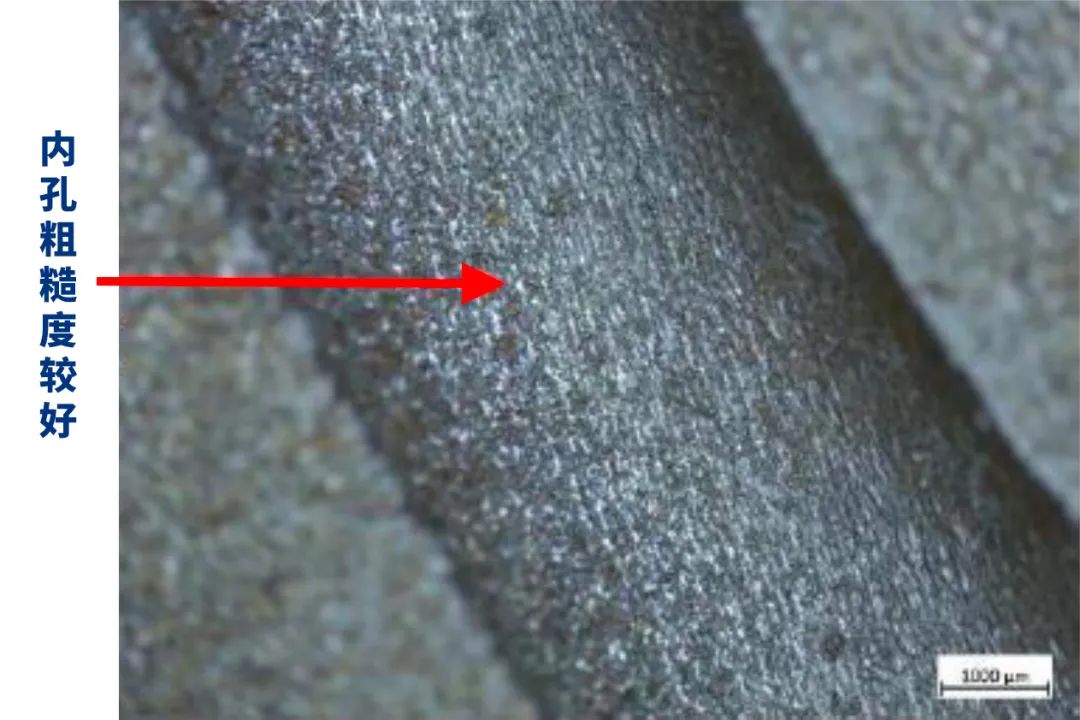

The continuous development of the manufacturing industry has also put forward new requirements for mold manufacturing: in addition to the complex structure, it requires high manufacturing precision, strong reliability, and long service life... It is difficult to process using traditional processes. The metal 3D printing technology has the characteristics of short production cycle and low cost of small batch production, so it has technical advantages for mold manufacturing, especially for the production of complex flow-type pore structure parts. In recent years, it has begun to show its edge in the field of domestic mold manufacturing.In practical application, LiM Laser used self-developed LiM-X400D equipment to print blank parts made of die steel for a car company. The profile of the inner flow channel of the part shows that the roughness of the inner hole is better and the overall quality of the round hole is higher.

Part internal flow path profile

Under the promotion of "intelligent manufacturing power", LiM laser will rely on years of accumulated experience in metal 3D printing technology, constantly break through the barriers of 3D printing technology, dig deep into the application field, and provide users in various industries with better equipment and more mature solutions.

Metal 3D printing

Related Articles

Market Activity