-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

Hollow cavity dot matrix structure, metal 3D printing technology for complex impeller parts manufacturing

Author: LiM Laser

Time:2023-03-27

Impeller and turbine parts play a very important role in modern industrial production, and common traditional manufacturing processes include casting, machining, and other methods. The development of metal 3D printing technology has provided new ideas for the design and manufacturing of such components.

Laser selective melting technology can manufacture parts by laser sintering powder. This process can achieve multiple recycling of raw material powder, with high material utilization rate. Combined with post-processing technology, it can achieve the forming and manufacturing of irregular curved surfaces, thin-walled structures, as well as closed and semi closed structures. Moreover, the production cycle of individual parts is short, especially suitable for customized production of small batch parts.

Ten laser printing processes

Many impeller and turbine parts have thin blades, which can easily cause slag inclusion, cold insulation, and other phenomena during casting. The cost of mold opening is high and the production cycle is long. Some impeller and turbine parts involve complex structures that are enclosed or semi enclosed. Compared to production methods such as five axis machining and laser welding, laser selective melting technology can achieve integrated forming, reducing the potential risks caused by process steps and welding gaps.

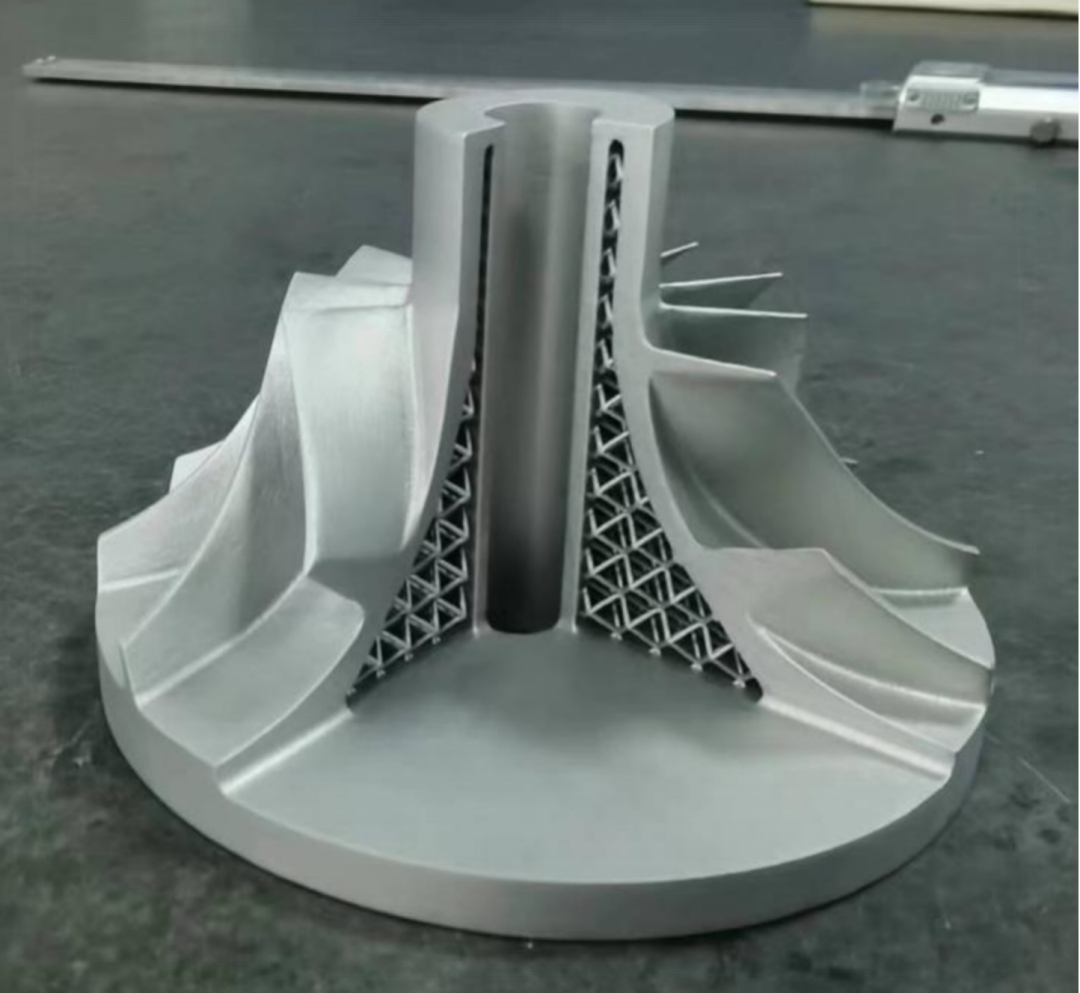

The following image shows the impeller exhibition parts designed and produced by laser, made of aluminum alloy (AlSi10Mg). The tensile strength of AlSi10Mg parts produced by the process team using laser selective melting technology exceeds the casting process AlSi10Mg solid solution+artificial aging (T6) standard by about 40%, and the elongation is 5-6 times higher than this standard.

LiM Laser printed impeller parts

Relying on the advantages of laser selective melting technology, the interior of components such as impellers and turbines can be designed as hollow cavities and lattice structures can be added, which can greatly reduce the weight of parts while maintaining their overall mechanical properties.

LiM Laser metal 3D printing impeller: internal hollow cavity+lattice structure

LiM Laser has printing parameters for aluminum alloy (AlSi10Mg) and various other metal powder printing parameters that can be applied to mass production. It is suitable for independently developed LiM-X series laser selective melting equipment, and the surface roughness of printed parts can reach Ra6.3 μ m. It can be used for the production and manufacturing of components in industries such as civil aerospace, energy and power, rail transit, automotive manufacturing, molds, education, and healthcare.

Relying on the research and development exploration of the technical team, Radiant Laser will continuously optimize the metal powder printing parameters, continuously upgrade the 3D printing process, provide users with high-quality solutions, and achieve increased production and efficiency.

Metal powder printing, metal 3D printing technology

Related Articles

Market Activity