-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

Ancient and modern meet, metal 3D printing technology to restore the "step moon bridge"

Author: LiM Laser

Time:2023-01-12

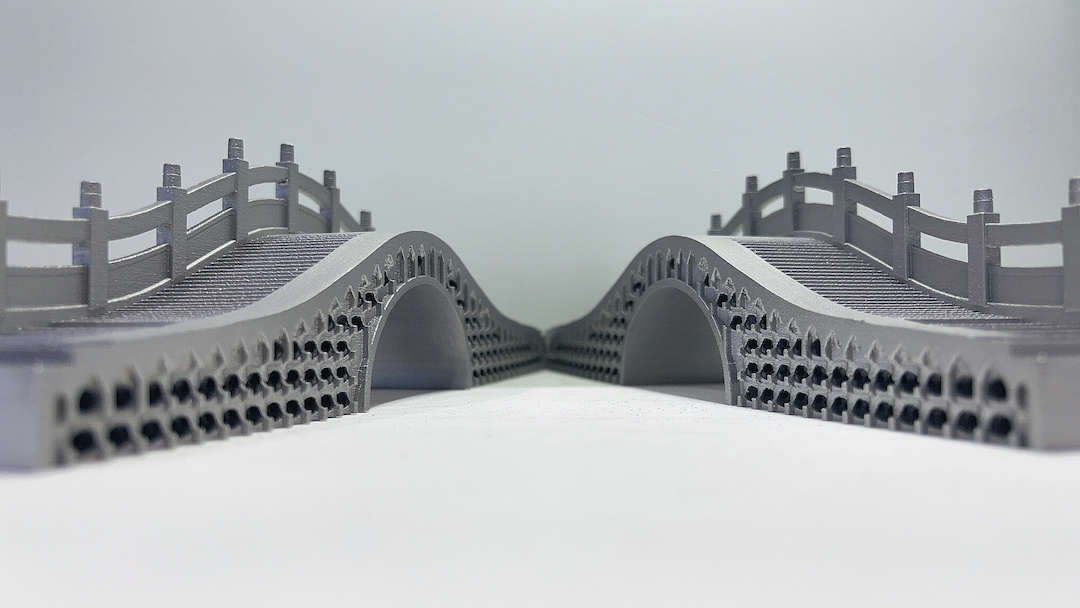

"Climb the Jiyang Buyue Bridge and connect heaven and earth like a magpie bridge". LiM laser with aluminum alloy material to restore the step of the moon bridge, with modern technology to perfectly demonstrate the beauty of the ancient building bridge.

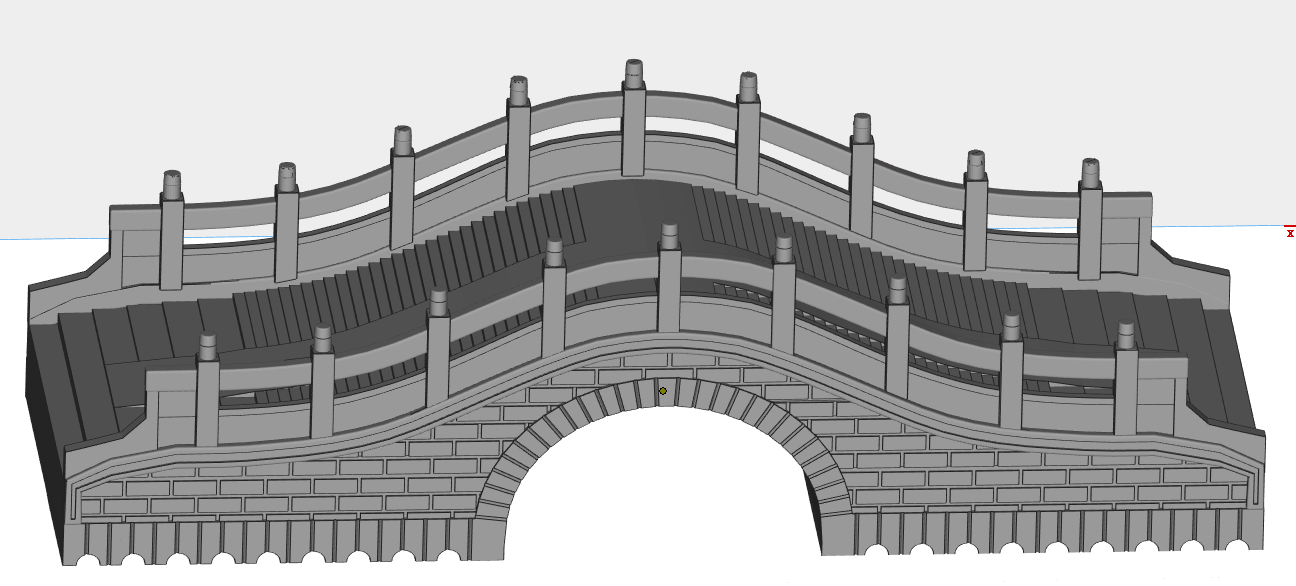

Buyue Bridge was built in the 14th year of Zhengde in the Ming Dynasty, with a total length of 127.5 meters and a width of 6.05 meters. The construction of the whole bridge does not require one nail and one rivet, which embodies the mature skills and superiority of my country's traditional bridge construction technology. The 42 wooden houses on the bridge are covered with tiles, and the wooden components crisscrossed up and down are closely connected with each other without any mistake. The shape is simple, magnificent and the structure is rigorous.LiM laser with the help of LiM-X260A series of equipment integrated forming rapid production, the series of equipment with fine light spot and other configuration advantages, to reproduce the beauty of the bridge art.

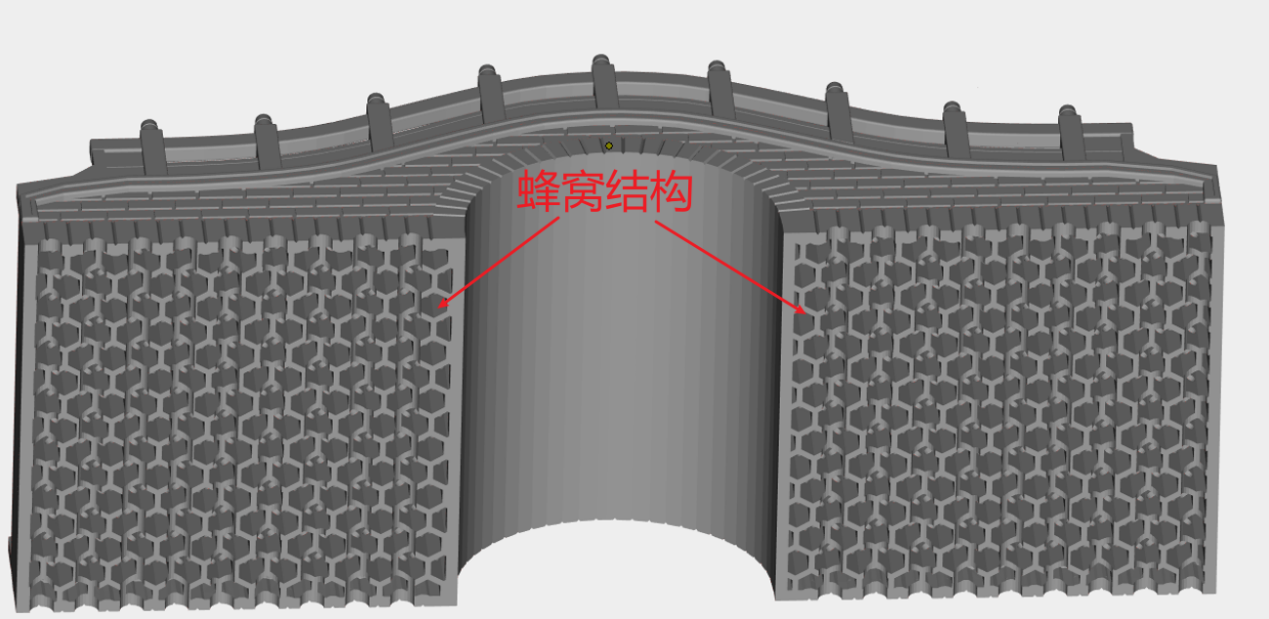

The printing size is 200mm * 60mm * 73mm, the theoretical weight is 410g, and the single piece printing time is 20 hours. The interior is filled with a honeycomb structure, which saves materials, compresses printing time, and retains a natural beauty; Precision construction and high surface finish fully demonstrate the "hard core" advantages of metal 3D printing technology in manufacturing complex structures and achieving lightweight parts.

Aluminum alloy for 3D printing: Aluminum is a metal with good strength to weight ratio, high thermal conductivity, high conductivity, and low density. Aluminum alloy for 3D printing has the characteristics of low density, light weight, high specific strength, high thermal conductivity, excellent physical and mechanical properties. Combined with the design freedom of 3D printing technology, it can go further and further in the fields of pressure vessels, hydraulic manifolds, brackets, high-strength structural components, etc. One nail, one rivet, crossing the river. Ancient bridges and beams embody the wisdom, craftsmanship, and aesthetic taste of the ancient laboring people; It also embodies the connotation of traditional Chinese culture and national spirit. Radiant laser inherits the quality of craftsmanship, restores the beauty of ancient buildings and bridges with modern technology, showcases exquisite metal additive technology, and outlines the "dream of corridor bridges" of every Jianou person.

Metal 3D printing

Related Articles

Market Activity