LiM laser uses metal 3D printing technology to reproduce the beauty of the power of the Hercules Cup

Author: LiM laser

Time:2022-12-28

On the early morning of December 19th Beijing time, the ultimate suspense of the Qatar World Cup was finally revealed. Argentina defeated France 4-2 in a penalty shootout to win the championship and win the World Cup, which symbolizes the highest honor in football.

Hercules Cup: 36.8 centimeters high, weighing 6.175 kilograms, with the main body of 4.97 kilograms cast from pure gold; The base is 13 centimeters wide and is embedded with four raised letters carved from malachite called "FIFA". The entire trophy looks like two Hercules holding up the Earth, hence its name.

LiM laser selection of titanium alloy materials, the useSelective Laser Melting Technology for Metal Additive ManufacturingOne-piece forming quickly produces Hercules cup ornaments with unique shape and full of strength.

Hercules Cup Original Mathematical Model

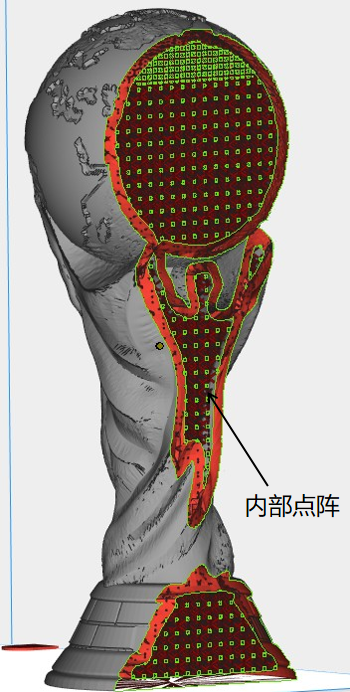

When constructing the model of the Hercules cup, the LiM laser technology team replaced the solid structure design of the original model with the design of the skin lattice structure. While realizing weight reduction, the Hercules cup has good pressure resistance in all directions, and the center of gravity of the parts is close to the middle position, making it more convenient to hold and place.

In the design of the Hercules cup, according to the weight and its strength requirements, the skin thickness is 4mm, the lattice cell size is 5mm, and the rod diameter is set to 0.75mm.

In addition, according to the characteristics of selective laser melting forming process, in order to ensure that the top small angle structure will not have defects such as shortage or warping during printing, dot matrix encryption is carried out on the structure with forming angle <45, and the cell size of the encrypted dot matrix is 2.5mm and the rod diameter is 0.75mm.

Lightweight Hercules Cup model

The advantages of skin lattice structure:

The lightweight processing method of filling lattice inside the outer skin is widely used in the lightweight manufacturing of parts in civil aerospace and other fields. Mainly has the following advantages:

- Reduce material costs

Lattice structures can reduce material waste by removing most of the material in non-critical areas. The material used to print the Hercules cup is titanium alloy, which is more expensive and can greatly save costs without sacrificing the structural rigidity and integrity of the parts.

- Lightweight

Through the lattice structure, the lattice parameters can be precisely adjusted to the physical load on the part, reducing the overall mass of the part by 60% or more.

- High surface area

The lattice structure can provide more curved surfaces and release a large amount of surface area, which has great advantages for products that promote heat exchange. The unique lattice structure can significantly increase the surface area, so as to achieve higher heat exchange efficiency in a more economical way.

- Impact resistance

Lattice structures are very effective in dissipating seismic and impact loads, because the unit structure helps the bending and energy distribution of the entire structure, and the lattice can be integrated into the product to reduce impact stress.

After lightweight design, the theoretical weight of the Hercules cup has been reduced from 3.85kg to 1.5kg, with a weight reduction of more than 60%. The single product is completed from printing to post-processing of parts, and the production cycle can be controlled within 5 days, fully demonstrating the potential of selective laser melting technology in the design and manufacture of lightweight parts and the advantages of rapid production in short cycles.

Metal 3D Printing Powerful Cup

When the traditional processing method is used to manufacture such ornaments, it is necessary to split the three-dimensional model into multiple parts for processing one by one, and finally to carry out splicing and combination, which not only takes a long manufacturing time, but also is difficult to meet the requirements of light weight, and the material loss is much. Metal 3D printing technology can solve these problems.

Digital manufacturing can break the constraints of part structure size, realize the production and manufacturing of parts with more complex structure, smaller size and more precise precision requirements, and make up for the problems of traditional industry production and manual difficulty.

In the future, LiM Laser will continue to play its advantages in metal 3D printing technology and provide various solutions for the production and manufacturing of more complex parts.

Metal 3D printing technology

Related Articles

Market Activity