LiM Laser Appears at TCT Exhibition

Author: LiM laser

Time:2018-03-04

TCT Asia Summit, the most authoritative additive manufacturing exhibition in the 3D printing industry, ended perfectly on March 3 in N1 Pavilion of Shanghai New International Expo Center, bringing a "3D printing" technology gluttonous feast to the audience. Tianjin LiM Laser Technology Co., Ltd. (hereinafter referred to as "LiM Laser") was invited to attend and participate in the event.

Looking at this year's TCT exhibition, the metal machine market has become more mature, with more than 50% of the exhibitors being metal 3D printing equipment manufacturers or suppliers of related materials and accessories. The two major categories of mainstream metal 3D printing technology, laser melting and electron beam melting, are the biggest highlights of this exhibition. Domestic metal 3D printing equipment of different application types and various super-large printing sizes have also appeared one after another. It can be seen that the domestic technology research and development level has improved rapidly, and the release of new equipment and technologies can be seen every year. Metal additive manufacturers are thriving and prospering day by day, with the potential of competing for success.

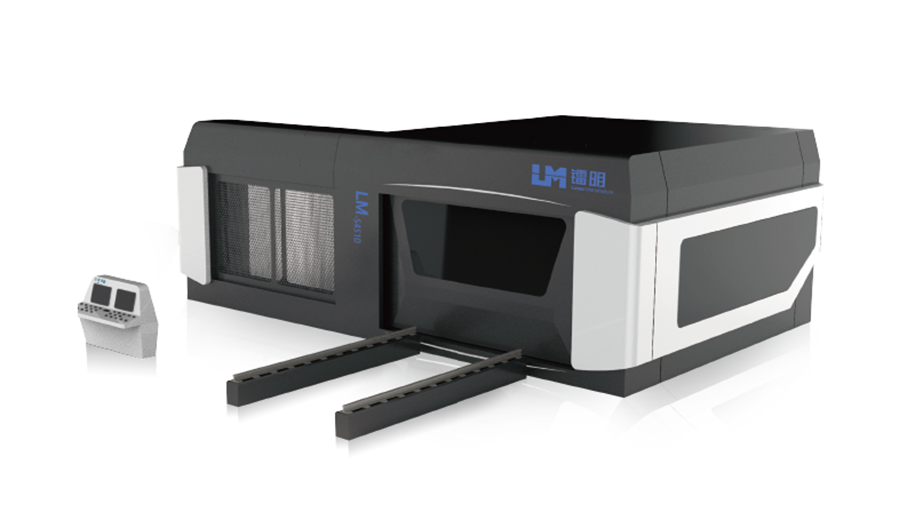

LiM Laser participated in the TCT exhibition for the first time and announced a variety of metal 3D printing equipment and auxiliary equipment. In view of the processing requirements of key and important components of major equipment, S4510, the first commercial laser deposition manufacturing equipment with the largest molding size in the world, has been independently developed, adding a heavy touch to the field of metal 3D printing and filling the technical gap of international laser deposition manufacturing super-large equipment.

S4510 uses 10000W fiber laser, spot diameter 2mm-14mm, equipped with LDMer intelligent control software, layered thickness 0.1 mm-1.5mm, printable size is the largest international 4500 mmx4000mmx1500mm, maximum forming efficiency can reach 1500 g/h, forming materials involve titanium alloy, high strength steel, high temperature alloy, aluminum alloy, stainless steel, etc. In addition, the S2510 of the molding format 2500 mmx2000 mmx1000 mm and the S1510 of the molding format 1500 mmx1000 mmx1000 mm have been mass-produced, while accepting customized laser deposition manufacturing equipment with different molding format sizes and optical system requirements.For the selection of laser melting equipment (SLM), LiM laser also proposed corresponding solutions for different industries. The self-developed X500A large-format four-galvanometer powder spreading equipment with a forming width of 500mm x 500mm x 600mm is suitable for the actual needs of high-precision large-size metal 3D printing in civil aerospace, automobile, abrasive and other industries. At the same time, two types of powder spreading equipment, X260A with a forming width of 250mm x 250mm x 420mm and X150A with a forming width of Ø140mm2x160mm, have been produced in batches, which can be applied to the routine application of metal 3D printing in various industries and the practical application of small experimental requirements such as education, jewelry and scientific research institutions.

3D printing

Related Articles

Market Activity