-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

LiM Laser Education Equipment Appears in the 45th World Skills Competition National Trial

Author: LiM Laser

Time:2018-06-28

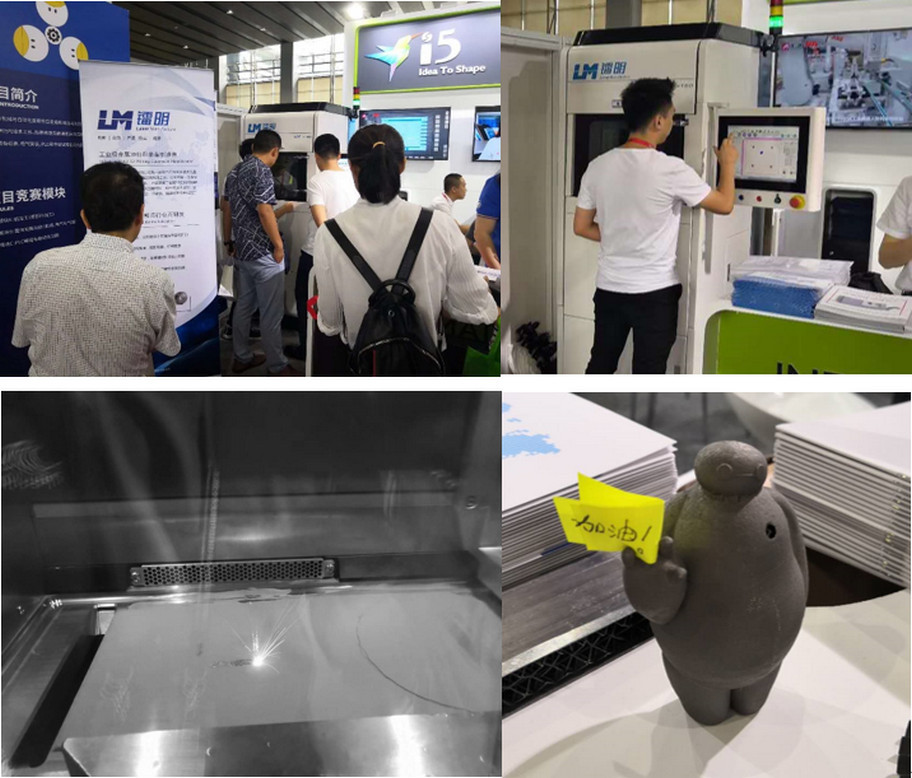

The 45th World Skills Competition National Trial is the first large-scale vocational skills competition held in accordance with the standards and procedures of the World Skills Competition. It is the largest competition scale, the most complete competition items, the highest competition standards, the most contestants, and the widest participation of all parties. A skill competition represents the highest level of my country's skill competition.Come on.from the whole country31provinces (autonomous regions and municipalities),21Industry (enterprise) team1359The contestants participated in the national trials, the competition in6Month28Day Closing in Guangzhou. Tianjin LiM Laser Technology Co., Ltd. (hereinafter referred to as "LiM Laser") was invited to attend and participate in the event.

The competition on the LiM laser for the first time announced for the education industry independent research and development of small metal3DPrint DeviceLM-X150A. The equipment is a professional laser selective melting equipment developed according to the characteristics of the education field, forming size φ.140*160 (Unit:mm),The equipment has a compact structure and can be equipped with a variety of sizes of tooling platforms according to different working conditions. It has flexible operation and stable performance. It has unique advantages in scientific research and development, practical training and teaching, and printing of small and complex parts.LM-X150A according to the technical characteristics of the specific environment and structure of the parts, the three-dimensional digital model can be established, and the small parts can be integrally formed by laser melting layer by layer. The process can realize on-demand manufacturing, reduce the burden of experimental teaching capital and increase flexibility. According to the requirements of the design scheme, we can also carry out research in the direction of lightweight, integration and topology optimization to realize "manufacturing everything you want".

Competition scene,LM-X150AThe printing effect of the equipment was good, attracting teachers and students from various colleges and universities to participate in the competition to stop and watch, and consulted in detail about the relevant performance of the equipment and metal.3DThe technical approach to printing, toLM-X150AThe equipment and the school-enterprise cooperation mode provided by LiM Laser on the construction of new engineering courses have generated great interest. The device prints9cmGao's "big white" model was loved by most audiences and took pictures together.

Metal 3D printing

Related Articles

Market Activity