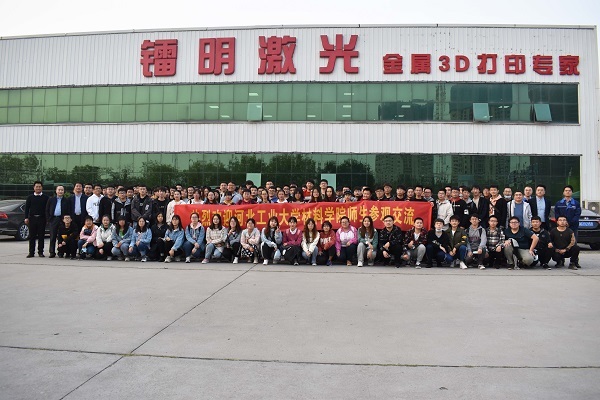

Teachers and students of Materials College of Hebei University of Technology came to our company to visit and exchange

Author: Radium laser

Time:2020-10-19

On October 15, under the leadership of Professor Wang Qingzhou, Professor Yang Yong, Professor Fan Yongzhe and Professor Zhao Lichen of the School of Materials of Hebei University of Technology, more than 120 senior students who are about to enter the workplace and scientific research life came to visit and practice in LiM Laser. Special lectures were held on the classification, process flow, practical application and future development of metal 3D printing technology, and on-site visits were carried out.

On the morning of the 15th, first of all, alumni of the Department of Materials of Hebei University of Technology and engineers of LiM Laser went to Beicchen Campus to carry out a rich exchange report, in addition to introducing the development and technical background of additive manufacturing technology for the younger students. Combined with actual cases, it also introduced the business segments (LENS near-net forming, SLM selection melting, WAAM arc welding additive) of the subsidiaries of TSC, which laid the groundwork for the subsequent site visit and aroused the students' strong interest. It also shares some of the failures and lessons that materials engineers encounter when entering the field of metal 3D printing.

The site visit took place in the afternoon of the same day, the students were divided into three groups, led by the staff and teachers of the school, visited the exhibition hall, laboratory, printing workshop, assembly workshop, machining post-processing workshop. The staff of LiM introduced the whole process from the entrance inspection of raw metal powder, the preliminary preparation of equipment printing, the actual laser melting forming process, the subsequent mechanical processing of parts, the size, quality inspection and the structural composition of SLM equipment, etc., so that the students had a preliminary understanding of the printing process of SLM process and the working principle of SLM equipment.

From the 15-year "Additive Manufacturing 2025", the 17-year "Additive Manufacturing Industry Development Action Plan" to the 2020 "Additive Manufacturing Standard Pilot Action Plan" all reflect the national level's attention and determination to develop 3D printing. The development of the additive manufacturing industry not only broadens the traditional processing field, but also brings more opportunities for material people to display their talents. We are in the ongoing industrial revolution. We are witnesses and participants. How fortunate we are.

Graduation always comes quietly and unexpectedly, and a person's development process will not always be smooth, but in the future, whether it is mild sunshine or urgent showers, they will be the elements that nourish our growth, because the seeds of hope have been sown to the fertile land, and one day they will take root and sprout into towering trees. I wish the 2018 materials students of Hebei University of Technology: Dapeng soared 90,000 miles a day with the same wind.

SLM devices

Related Articles

Market Activity