-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

Additive person, come and get your exclusive badge.

Author: LiM Laser

Time:2022-07-04

The badge is one of the corporate logos that everyone in the workplace is familiar with. I think everyone has worn badges of different materials: stainless steel, acrylic, copper, titanium, etc. However, no matter what material it is, it is made and formed through traditional processing technology. As an additive manufacturing and processing enterprise, do we want to have a badge with unique characteristics of additive people?

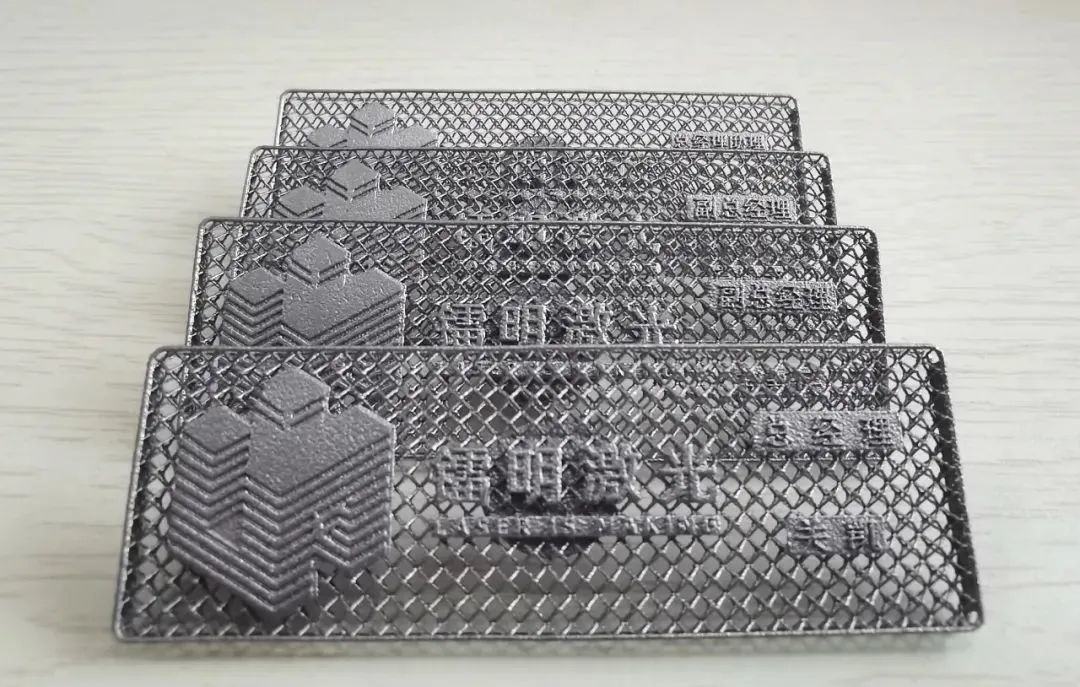

Recently, Tianjin LiM Laser Technology Co., Ltd. (hereinafter referred to as "LiM Laser")Metal 3D printing equipmentA metal 3D printing badge exclusive to the additive person has been produced. The outline of the badge is a cuboid structure of 60mm × 20mm × 20mm. In the printing process, we focused on solving two problems: one is how to ensure the beauty, but also reflect the characteristics of its 3D printing industry; the other is How to take into account its practicality and comfort. In view of these two problems, we use a dot matrix structure with a 2mm package circle and a 0.2mm rod diameter to fill, and then the contour of the breastplate is lattice-processed. The lattice structure is light in weight and high in strength. At the same time, it can also reflect the characteristics of our metal 3D printing industry, which can manufacture complex structures. Through the continuous adjustment of the path parameters of the BP software, the limit size was finally broken through, and the badge product with a diameter of 0.2mm was successfully printed.

This badge is a printing process completed on the LiM-X260 series equipment independently developed by LiM Laser. Two metal materials, high-temperature alloy and titanium alloy, were used respectively, and finally showed a good printing effect. The forming size of LiM-X260 series equipment is 260mm × 260mm × 430mm (including 30mm standard substrate thickness). The equipment adopts modular design and can customize laser power, galvanometer number, forming size, monitoring module, etc. according to customer requirements. Each module is independently designed and widely used in series products with good reliability. The stability of customized products is equivalent to that of standard products. LiM laser also has a consulting team with more than 10 years of accumulated experience in the field of additive manufacturing, which can help customers optimize the process and improve the product qualification rate.

Previous article

Related Articles

Market Activity