TCT ASIA 2022 Successfully Concluded | TSC & Review of LiM Laser

Author: LiM Laser

Time:2022-11-07

From November 3 to November 5, TCT Asia Exhibition opened in Shenzhen. As a leader in the field of metal 3D printing, TSC-LiM Laser and LiM-X260 series of equipment appeared at the exhibition. At the same time, metal 3D printing application cases applied in civil aerospace, energy and power, automobile medical treatment, education, cultural creation and other fields were displayed, which attracted the attention of the audience.

Application case show: "the beauty of science and technology" attracts attention

The 1.6m high dot matrix structure exhibition piece formed by continuous printing for 30 days, the infrared suppression shell integrally formed with petal-shaped curved surface structure, the denture that can be quickly customized, the creative Chinese dragon with vivid and flexible joints, the small turbojet engine shrinkage ratio piece, the human bone structure piece, the umbrella cabin flange......

Metal 3D printing creative parts

Metal 3D printing Chinese dragon, dragonfly

Infrared suppression shell

Metal 3D printing technology can make complex structures integrally formed. Compared with traditional processes, it can greatly reduce product production costs, improve product production efficiency, and give room for fantastic designs.

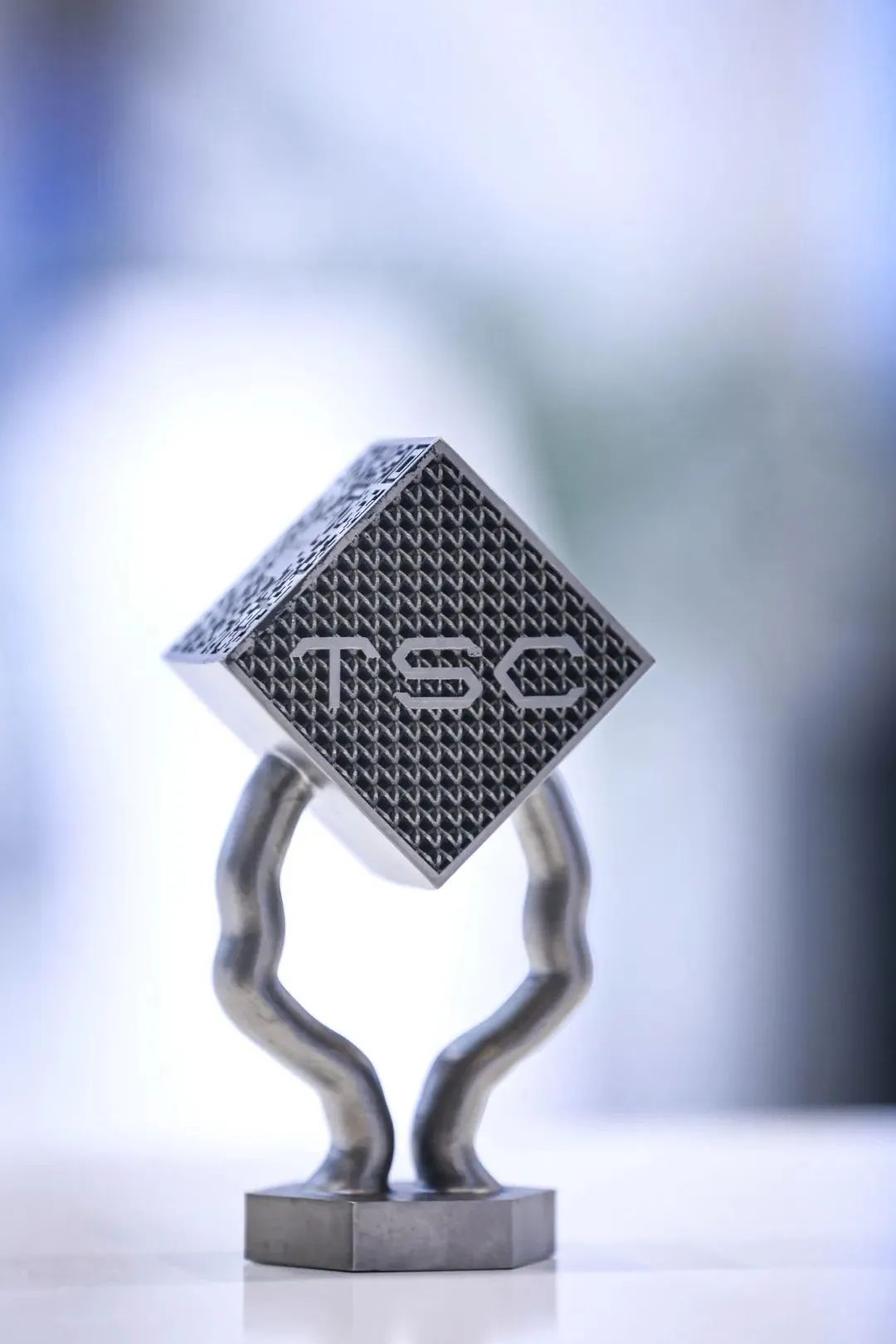

Metal 3D printing company logo

Metal 3D printing Eiffel Tower

The collision and blending of design and technology have allowed the audience to stop and understand.

LiM-X260 Appearance: "C Debut" Gather Eyes

LiM-X260 Series Equipment

LiM-X260 series equipment has been well received by customers since its release. The forming size of 260mmX260mmX430mm can reach a forming speed of 45cm ³/h with dual lasers. It supports forming materials such as titanium alloy, aluminum alloy, high temperature alloy, cobalt chromium alloy, stainless steel, die steel, copper alloy, etc., and is widely used in civil aerospace, molds, Education and other fields. Exhibition site, attracted friends from all walks of life to understand the concern.

New product online release: communication and interaction "zero distance"

In this exhibition, TSC-LiM Laser opened the mode of online and offline linkage, and released a new generation of large-scale products for everyone through online live broadcast.Metal Additive Manufacturing Equipment LiM-X800. New product release, live to see the exhibition, exchange and interaction ...... so that friends who can not be present at the scene can also be the first time to understand the new generation of LiM laser flagship products.

LiM-X800 Equipment

This live broadcast attracted nearly 30,000 people to watch online. The audience left messages and interacted, shocked by new products and breakthroughs, and professional audiences asked questions and consulted to learn more about LiM-X800 equipment. Friends who missed this live broadcast can scan the two-dimensional code below to watch the live broadcast.

In the future, TSC & LiM Laser will continue to develop metal 3D printing technology, continue to carry out industrial technology innovation, and provide users with more complete and high-quality metal 3D printing overall solutions.

Metal 3D printing

Related Articles

Market Activity