-

About LiM

About LiMLiM Laser is committed to providing global customers with advanced additive manufacturing equipment, supporting auxiliary equipment and 3D printing services.

-

Products

ProductsRadium Laser has independently developed LiM-X series of selective laser melting equipment, LiM-S series of coaxial powder feeding equipment, LiM-R series of laser cladding equipment and customized equipment for special industries.

-

Solution

SolutionRadium Laser provides differentiated metal 3D printing solutions for different industries, focusing on user needs and continuing to create greater value for users.

-

Service Support

Service SupportRadium laser with a professional team, rapid response, efficient service to provide users with applications and technical support services.

-

News

NewsRadium bright laser at any time access to the latest information -- enterprise development, honor information, the latest achievements such.

-

Marketing Dynamics

Marketing DynamicsFocus on the industry event and share details of various activities of radium LiM Laser!

-

Contact Us

Contact UsWelcome to contact us for more information Tel: 86-022-27914042 18622468793

LiM laser on the list of the Ministry of industry and information technology 2022 key products, process "one-stop" application demonstration list

Author: LiM Laser

Time:2023-02-02

In order to accelerate the promotion and application of high-quality basic products and advanced technologies, and promote the formation of an industrial chain collaborative innovation pattern of mutual integration, symbiosis, division of labor and cooperation, the Ministry of Industry and Information Technology and the State-owned Assets Supervision and Administration Commission of the State Council jointly organized the 2022 key products and processes "one-stop" application demonstration work, and selected the 2022 key products, process "one-stop" application demonstration direction, promotion agencies and participating units list.

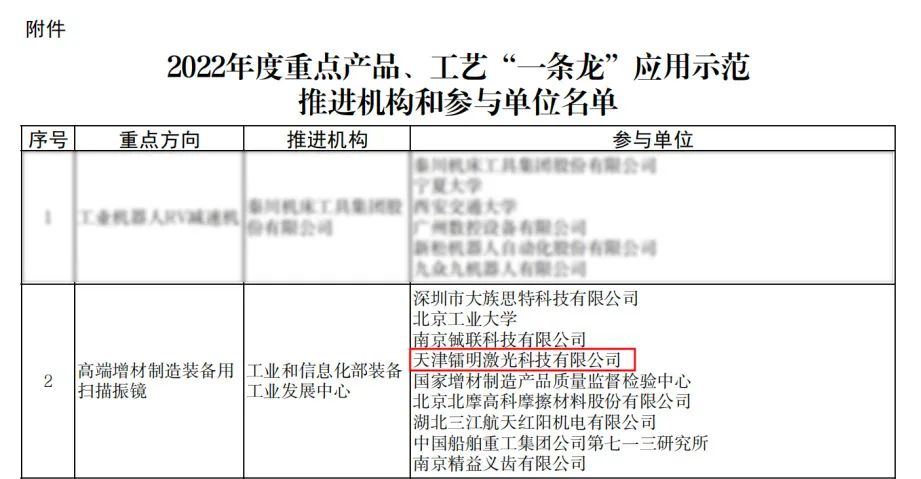

LiM laser as a "high-end additive manufacturing equipment with scanning galvanometer" application demonstration key direction of the participating units, the list.

As a leading provider of overall solutions for metal 3D printing in China, LiM Laser has an annual production capacity of 150 sets of various types of 3D printing equipment, and has more than 70 core technology patents. Over the years, it has focused on technological innovation and research and development, and has continuously overcome a number of technical problems. At present, the company's independent research and development of a series of equipment and related technologies have been widely used in civil aerospace, energy power, automobile manufacturing, mold, medical, education and other fields.

This selection is a review of the LiM laser inMetal Additive ManufacturingFull affirmation of R & D innovation and industrialization capabilities in the field. In the future, the company will take this opportunity to closely focus on the development trend of the additive manufacturing industry, continue to upgrade industrial technology, increase core technology research, and work with upstream and downstream enterprises to strengthen industrial chain collaboration and innovation, and contribute to the high-quality development of my country's metal additive manufacturing industry.

Related Articles

Market Activity